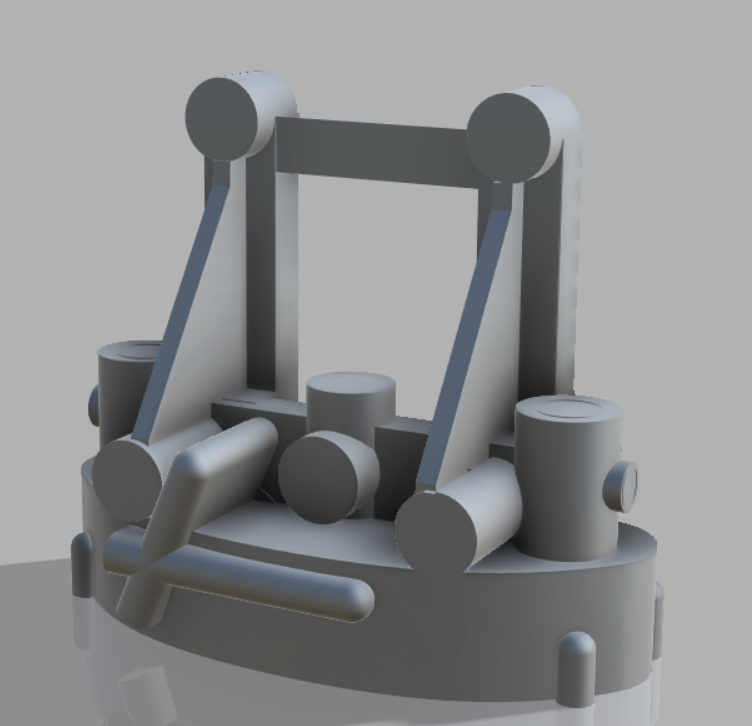

Dentist Chair

RAPID PROTOTYPING & SMALL BATCH PRODUCTION

Rapid prototyping serves as an invaluable tool for businesses aiming to swiftly iterate and test their product designs, enabling them to refine concepts and identify improvements efficiently. For small batch production runs, 3D printing technologies (FDM) and (SLS) provide a cost-effective and agile solution, enabling companies to produce limited quantities of customized components or products without the need for expensive tooling or lengthy setup times

Fused Deposition Modeling

or FDM 3D Printing

FDM printers work by heating a thermoplastic filament to its melting point and then extruding it, layer by layer, to create a three dimensional object.

FDM printers are relatively inexpensive and easy to use, making them a popular choice for home and small-scale 3D printing

Stereolithography (SLA)

Stereolithography works by using a photopolymer resin that is cured by exposure to light.

The machine traces out the desired geometry layer by layer using a computer-controlled moving laser beam.

The beam is directed by mirrors that are positioned around the build platform.

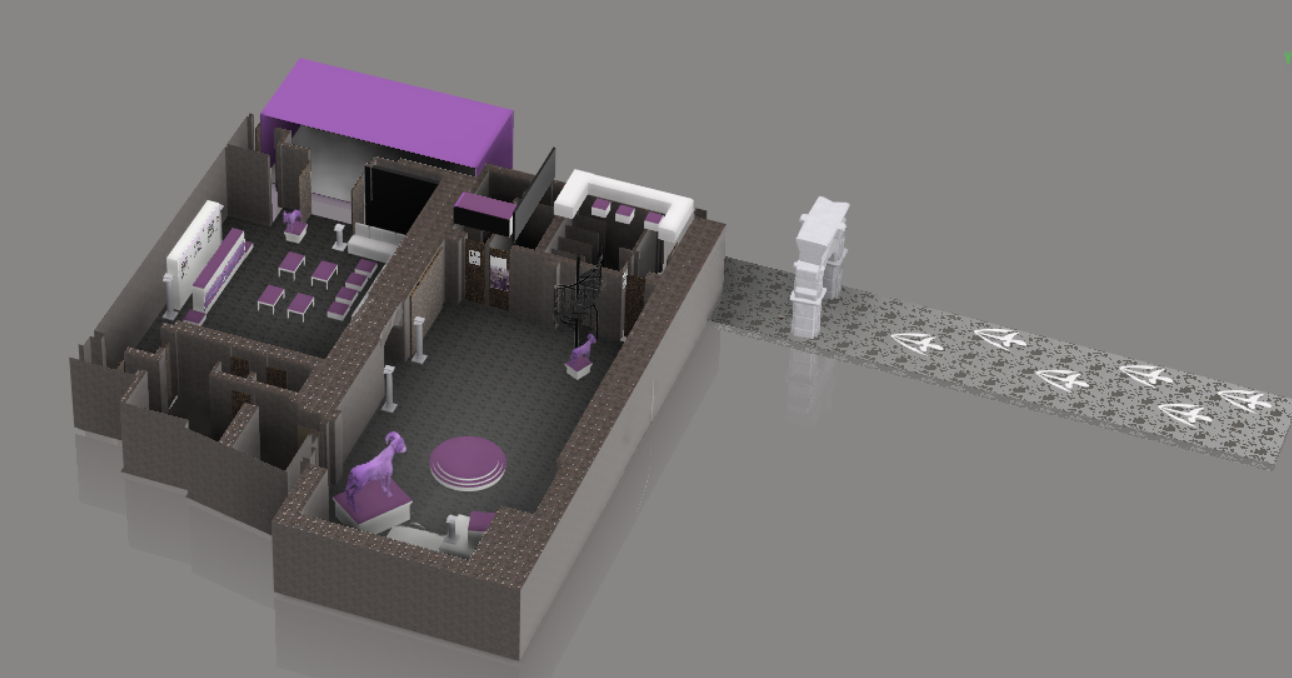

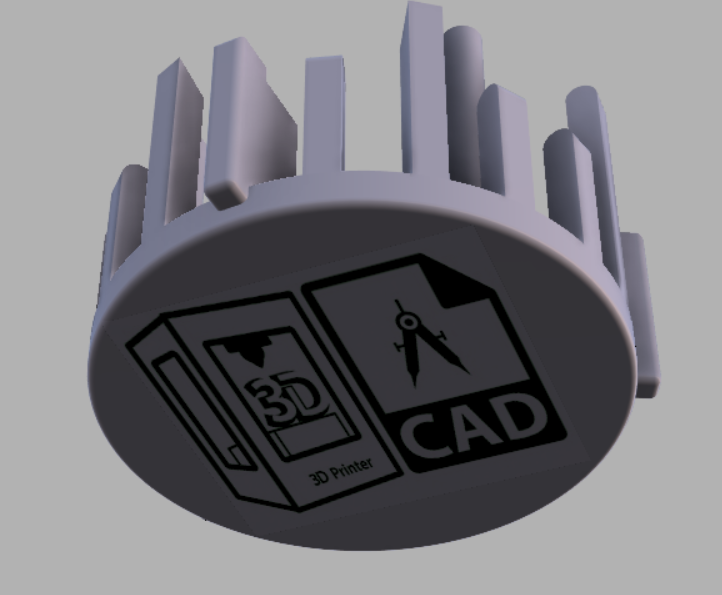

CAD DESIGN & REVERSE ENGINEERING

When it comes to certain projects, a computer-aided design, or CAD, can be extremely beneficial. A main advantage to using CAD is the fact that it provides experts with greater accuracy. This is done by replacing manual drafting with electronic design software, such as SketchUp, Fusion 360, or AutoCAD Design Edition.

Ever since the inception of our company, we have encouraged every single employee to focus on only one thing- quality. We have always strived to create products that achieve the highest standards and meet our customer's expectations.

No matter the project, we always ensure that each and every element of the project is produced to perfection and is the best possible outcome. We use the best materials and processes to ensure that the quality of our products is unrivalled, and that our customers get the most out of them.

This focus on quality and customer satisfaction has been the cornerstone of our success and has allowed us to build a strong and loyal customer base. Our customers know that when they entrust us with their projects, they will get the best results.

We are proud to have created and maintained so many successful projects over the years and have provided our customers with products that exceed their expectations. We will continue to strive for excellence and never stop searching for new ways to improve our products and services.

It all started with a request from a dentist. He had just finished with a patient when he noticed the examination light on his chair had burnt out. It was a crucial part of the chair and he couldn't continue his work without it. He went to us in search of a replacement.

We had no clue how to recreate the exact duplicate of the original part. But that didn't deter our team spirit. We studied the design closely and soon came up with a plan to reverse engineer the part. Our team worked day and night with utmost dedication and finally, we were able to create an exact replica of the damaged part.

We reproduced the part using ABS plastic and it was surprisingly similar to the original part. Soon, we delivered it to the dentist and it worked like a charm. Our team was so inspired by the success of this project that it motivated us to take on more challenging tasks.

It was truly an inspirational experience for us, to see how something as complex as a dental chair's examination light can be recreated and be of use again. It showed us that even the most daunting of tasks are achievable and encouraged us to take risks and explore ourselves more.

ABS plastics were known for their amazing heat tolerance and durability, but few knew just how remarkable these properties could be until the scientists at Edwards Industries got to work. They worked and tested for months, and the results were nothing short of extraordinary.

The ABS-printed parts they created could survive multiple impacts without any damage and their tolerance for extreme temperatures was among the highest of any material. The engineers were so impressed, they began testing its other properties and the results continued to amaze.

The rigidity, impact resistance, weldability, and abrasion and strain resistance were all incredibly impressive. Even more impressive were the material's dimensional stability and high surface brightness, which gave it an almost magical quality.

As word of the ABS plastics' extraordinary properties spread, so did the demand, and it wasn't long before Edwards Industries was a household name. From aerospace to automotive and beyond, the ABS plastics revolutionized the industry and opened up a whole new world of possibilities.

Today, ABS plastics are used for a variety of applications and their excellent qualities have made them a go-to material for engineers and scientists alike. What started as a curiosity has now become the gold standard for a variety of projects and it seems the possibilities with ABS plastics are only just beginning.

About Us

All Rights Reserved | Mitchell and Son Additive Manufacturing Ltd | Registered Company in England and Wales | Company Number : 12038697

| Public Liability Insurance no. 14615097

Insurer: AXA XL