Rubix Industrial Supply

RAPID PROTOTYPING & SMALL BATCH PRODUCTION

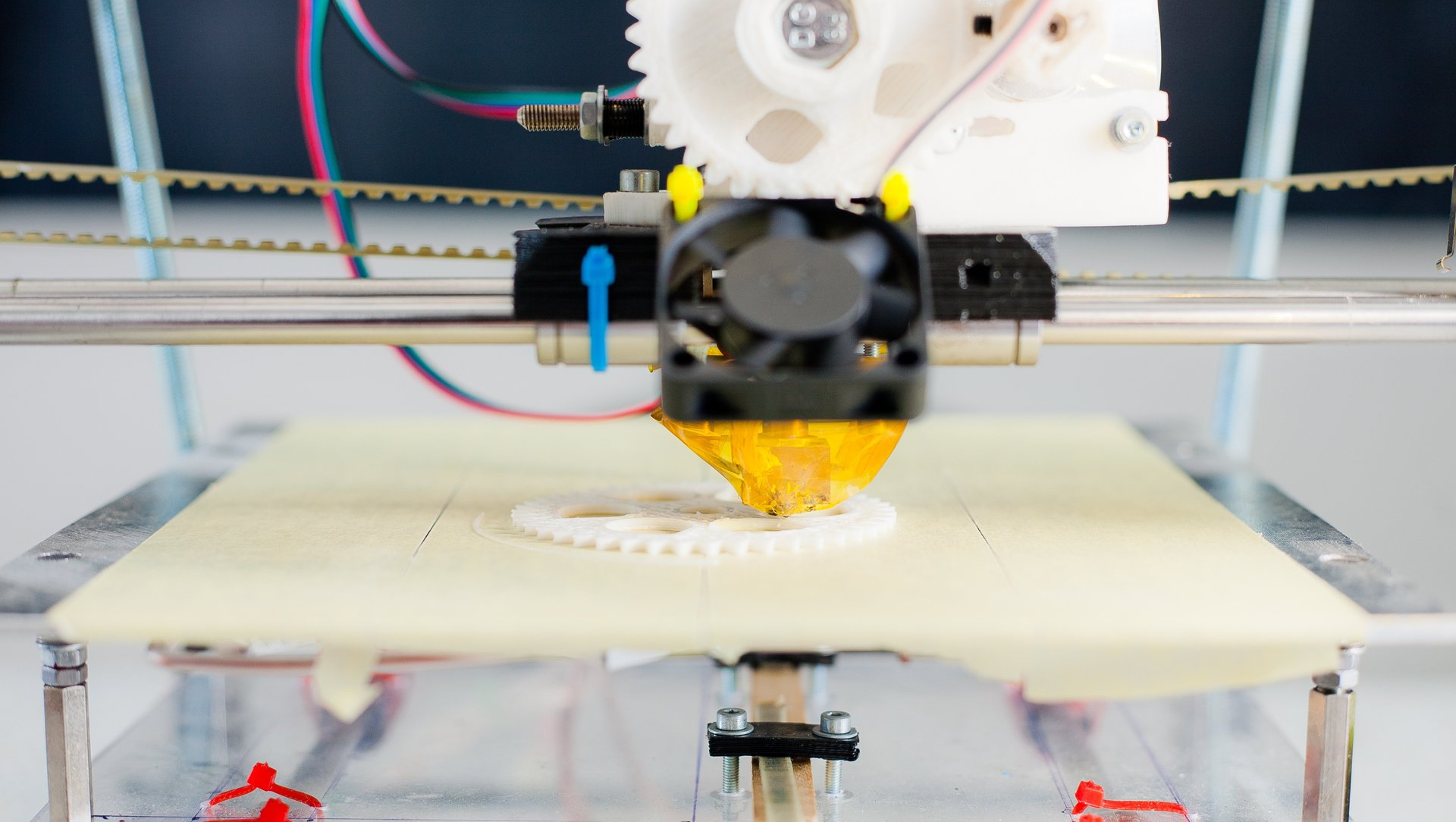

Rapid prototyping serves as an invaluable tool for businesses aiming to swiftly iterate and test their product designs, enabling them to refine concepts and identify improvements efficiently. For small batch production runs, 3D printing technologies (FDM) and (SLS) provide a cost-effective and agile solution, enabling companies to produce limited quantities of customized components or products without the need for expensive tooling or lengthy setup times

Fused Deposition Modeling

or FDM 3D Printing

FDM printers work by heating a thermoplastic filament to its melting point and then extruding it, layer by layer, to create a three dimensional object.

FDM printers are relatively inexpensive and easy to use, making them a popular choice for home and small-scale 3D printing

Stereolithography (SLA)

Stereolithography works by using a photopolymer resin that is cured by exposure to light.

The machine traces out the desired geometry layer by layer using a computer-controlled moving laser beam.

The beam is directed by mirrors that are positioned around the build platform.

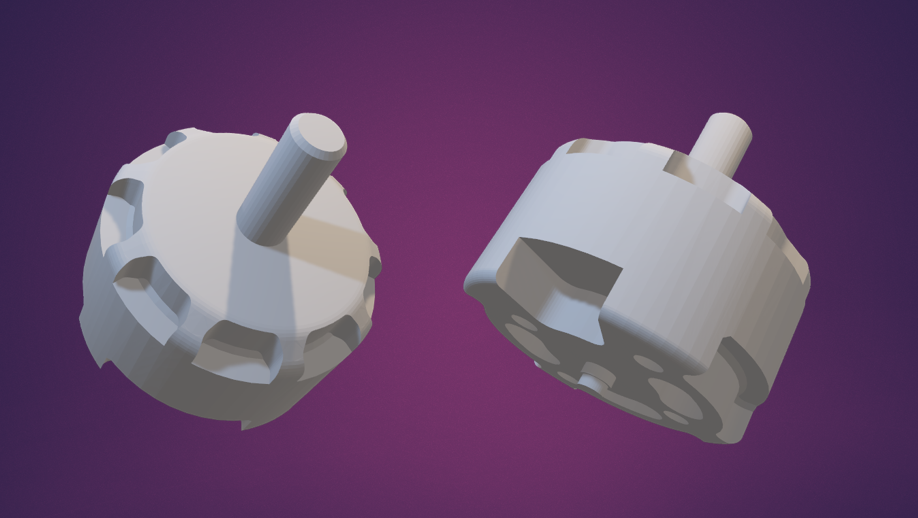

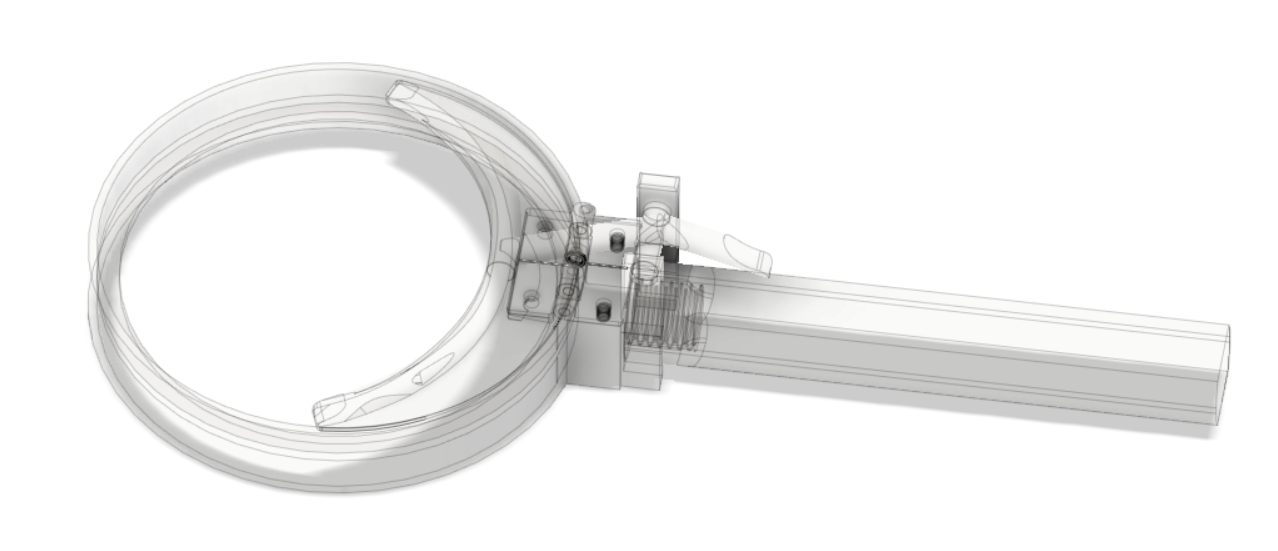

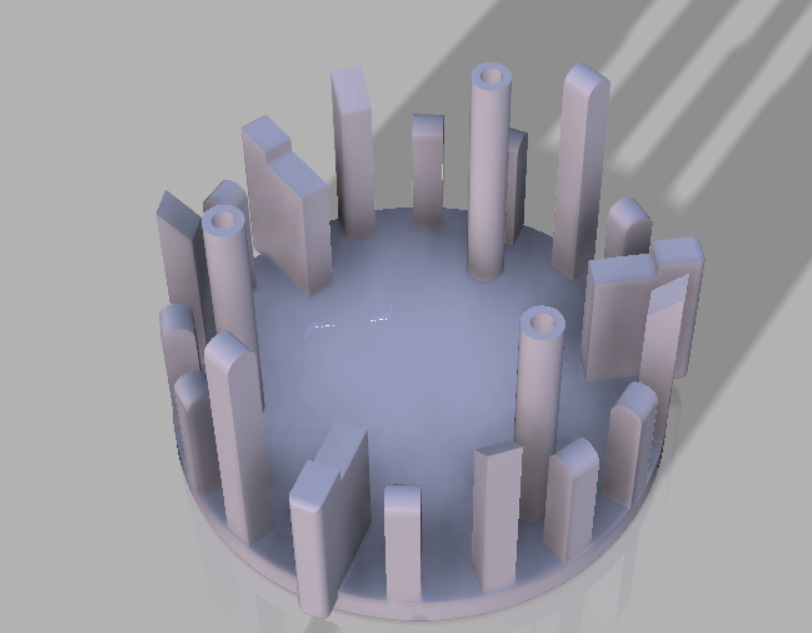

CAD DESIGN & REVERSE ENGINEERING

When it comes to certain projects, a computer-aided design, or CAD, can be extremely beneficial. A main advantage to using CAD is the fact that it provides experts with greater accuracy. This is done by replacing manual drafting with electronic design software, such as SketchUp, Fusion 360, or AutoCAD Design Edition.

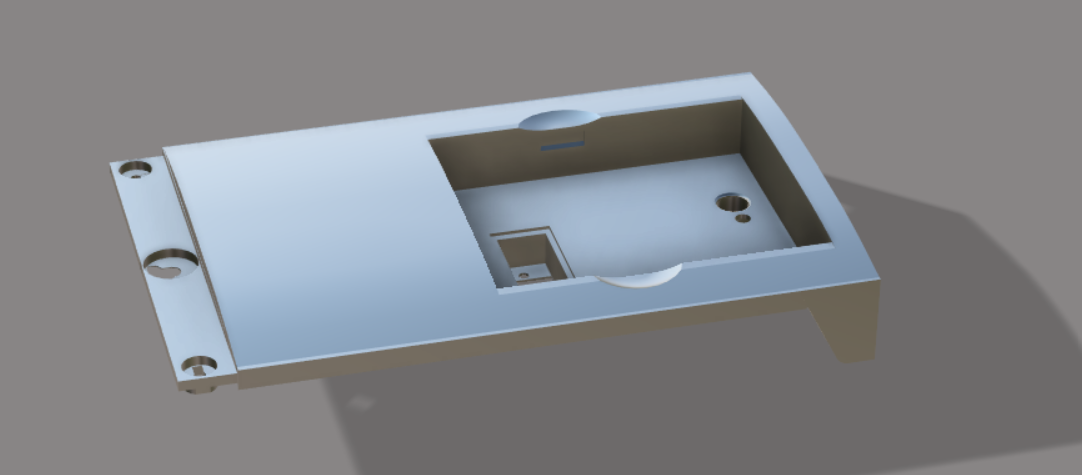

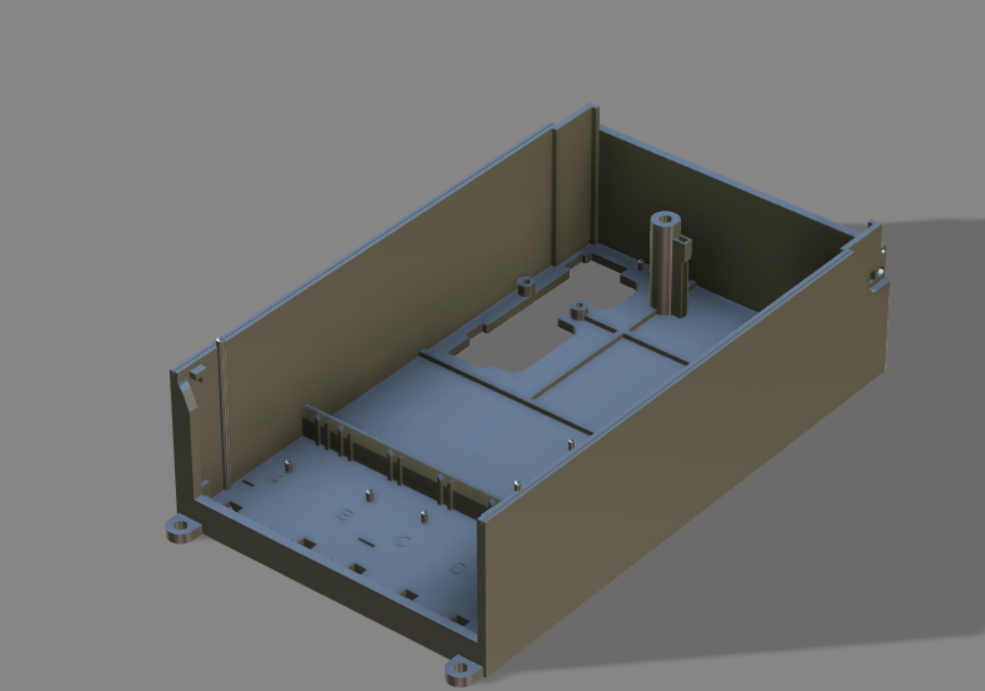

There was something strange about the request we had just received. On the surface, it seemed typical enough: a company had emailed us asking us to reverse engineer a PCB enclosure that was used for overhead cranes. What was strange was the fact that the original parts had started to deteriorate due to the over exposure of heat in the environment that they were found in. It seemed strange that something designed to be used outdoors would fail so quickly.

We set about creating the 3D Model and printing the parts. We had been asked to use ABS plastic, and we were determined to do the best job possible. We knew that by putting the parts inside a mounting enclosure, we could give the circuit board additional protection against external contaminants as well as accidental damage or breakage. We also knew that a PCB mounting enclosure lent a more finished look to the device.

We worked diligently all day, and eventually, everything was completed. We looked at our work with pride as we knew we had done the best job possible. We packaged everything up and sent it back off to the client.

We never heard what happened to the PCB enclosure, but spending all that time working on it certainly gave us an appreciation for the complexity of the task. It was a reminder to us that those who design these products take a lot of time and effort to ensure that their products last and perform well in even the harshest of conditions.

We began by creating a 3D Model of the parts, and soon it was time to 3D print them in ABS plastic. We were careful to make sure that they fit correctly into the mounting enclosure, providing additional protection against external contaminants and accidents. We knew that this would give the device a more finished look and feel, while also doing its job of protecting the PCB.

It took us several days of non-stop work, but in the end, we had created a mounting enclosure that perfectly fit the needs of the company. We took a step back and were proud of our work, knowing that we had given the device the protection it needed.

We hope that our work will continue to help the company for years to come and that the circuits will be safe and sound.

We then 3D printed the enclosure using ABS plastic to create a perfect replacement part. See how we turn a problem into a solution with our reverse engineering and 3D printing services!

We can help. Our additive manufacturing process is perfect for low production runs, and we can guarantee identical specs on every order for the best unit price. Contact us today to learn more.

- Dedicated project managers

- All the features listed in Rapid prototyping to produce small production runs

- Application engineers for cost optimisations

- 3D Model Store ensuring quick accessibility to spare parts

- Custom UK Based Company, that has global manufacturing reach.

- Looking for an additive manufacturing service near me?

- We are as near to you as your computer.

We offer manufacturing services for low production batch runs.

If you're looking for a quick, easy and cost-effective way to produce low production batch runs of your product, Additive manufacturing (3D printing) is a great option.

About Us

All Rights Reserved | Mitchell and Son Additive Manufacturing Ltd | Registered Company in England and Wales | Company Number : 12038697

| Public Liability Insurance no. 14615097

Insurer: AXA XL