3D Printed ASA

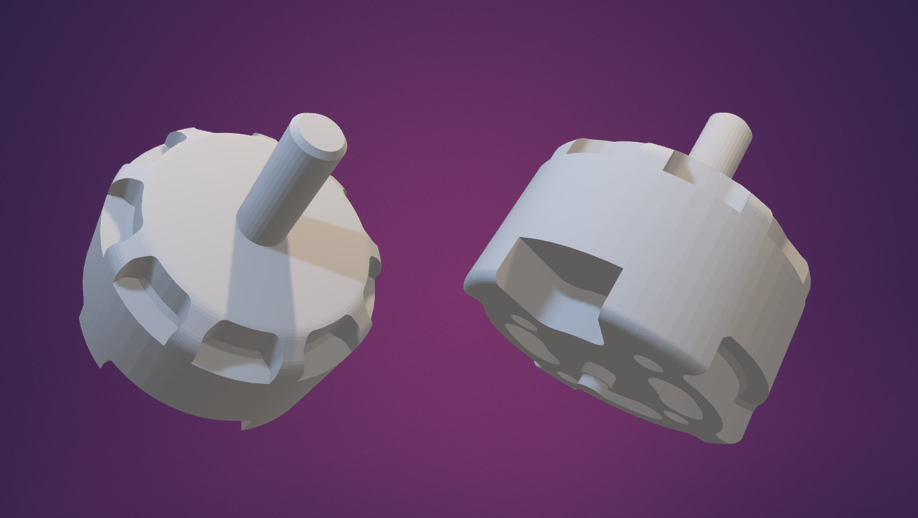

RAPID PROTOTYPING & SMALL BATCH PRODUCTION

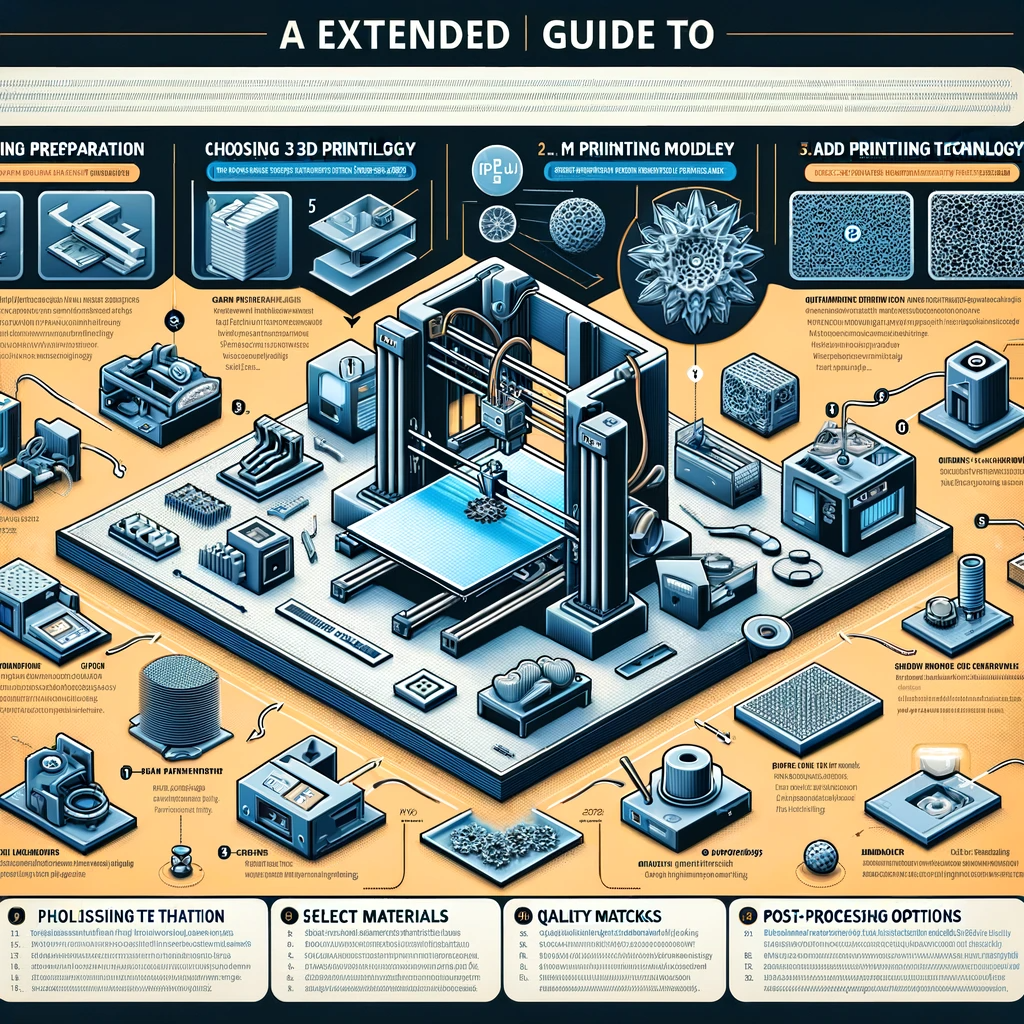

Rapid prototyping serves as an invaluable tool for businesses aiming to swiftly iterate and test their product designs, enabling them to refine concepts and identify improvements efficiently. For small batch production runs, 3D printing technologies (FDM) and (SLS) provide a cost-effective and agile solution, enabling companies to produce limited quantities of customized components or products without the need for expensive tooling or lengthy setup times

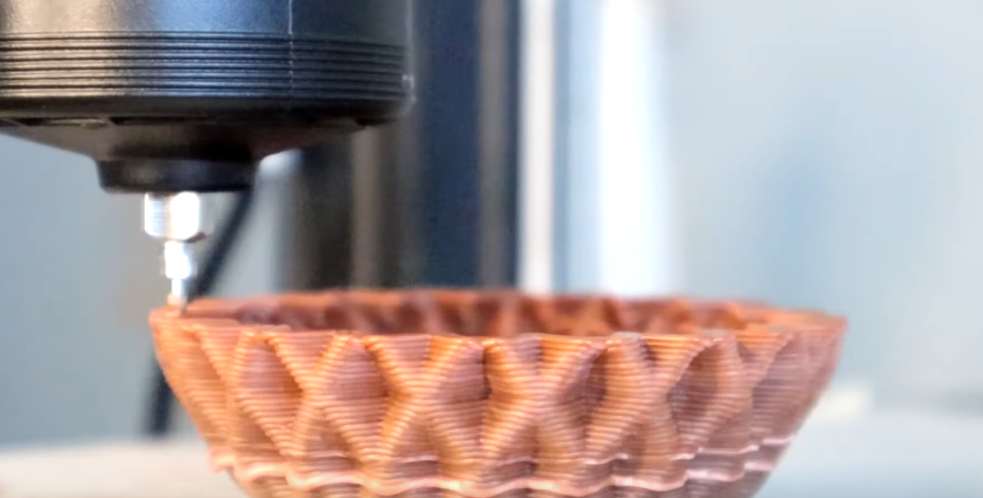

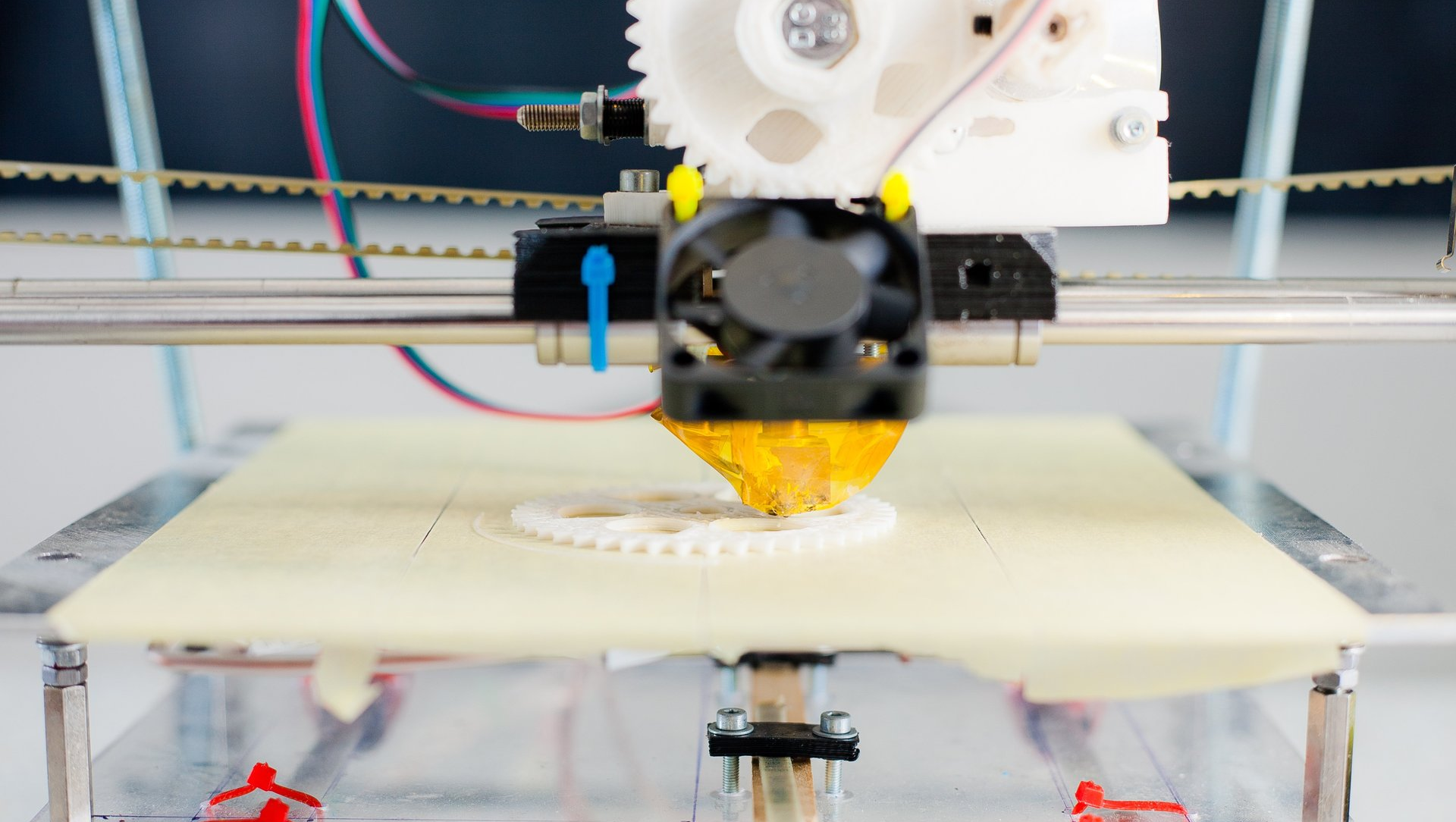

Fused Deposition Modeling

or FDM 3D Printing

FDM printers work by heating a thermoplastic filament to its melting point and then extruding it, layer by layer, to create a three dimensional object.

FDM printers are relatively inexpensive and easy to use, making them a popular choice for home and small-scale 3D printing

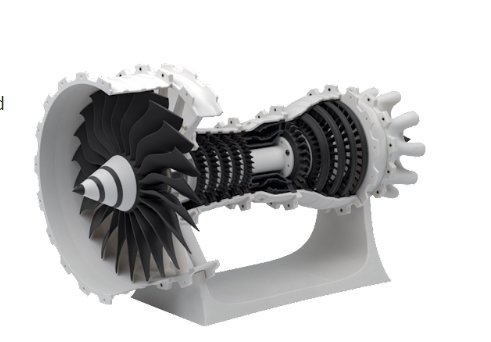

Stereolithography (SLA)

Stereolithography works by using a photopolymer resin that is cured by exposure to light.

The machine traces out the desired geometry layer by layer using a computer-controlled moving laser beam.

The beam is directed by mirrors that are positioned around the build platform.

CAD DESIGN & REVERSE ENGINEERING

When it comes to certain projects, a computer-aided design, or CAD, can be extremely beneficial. A main advantage to using CAD is the fact that it provides experts with greater accuracy. This is done by replacing manual drafting with electronic design software, such as SketchUp, Fusion 360, or AutoCAD Design Edition.

SOME INFOMATION ABOUT THE MATERIAL

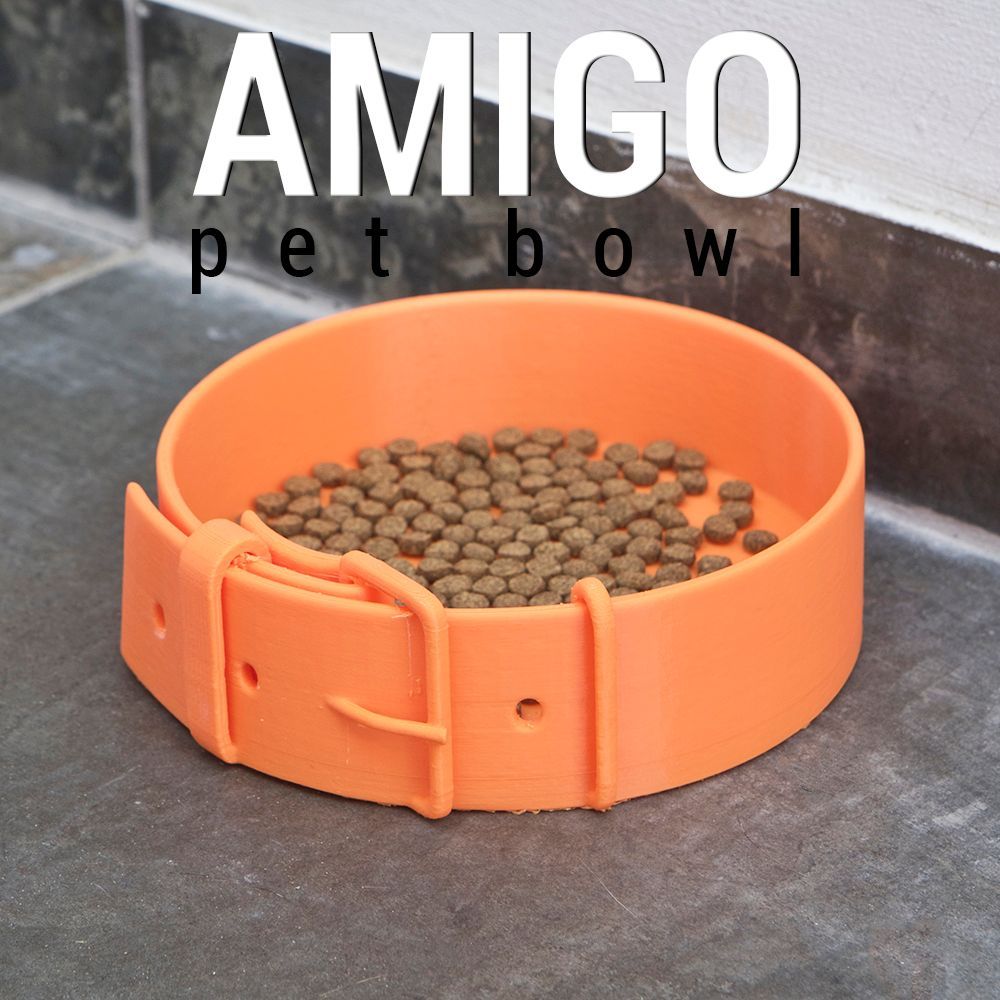

Asa is a type of plastic filament that is becoming increasingly popular for 3D printing. It is a thermoplastic, which means it can be melted and reformed multiple times. Asa is a strong and durable plastic, making it ideal for 3D printed objects that will be used outdoors or in harsh environments. It is also resistant to UV light and water, making it ideal for prototypes or final products that will be exposed to the elements.

Asa is not the only type of filament available for 3D printing, but it is one of the most versatile. It can be used to create a wide variety of objects, from small models to large pieces of machinery. Asa is also available in a wide range of colors, allowing you to create objects that are both functional and visually appealing.

As a counterpart as ABS, ASA filament generates toxic fumes when printing so it is very important to print in a place with good ventilation.

Tensile Strength Yield, 3.20 mm ASTM D638 47.1 MPa

Contact us

Address

Enterprise House

Ocean Way

Ocean Villiage

Southampton

SO14 3XB

(+44) 02381244996

(+44) 07876131539

info@mitchellsson.co.uk

ASA (Acrylonitrile Styrene Acrylate) is a 3D printing filament known for its strength, durability, and UV resistance. Here is some technical data on 3D Printed ASA filament:

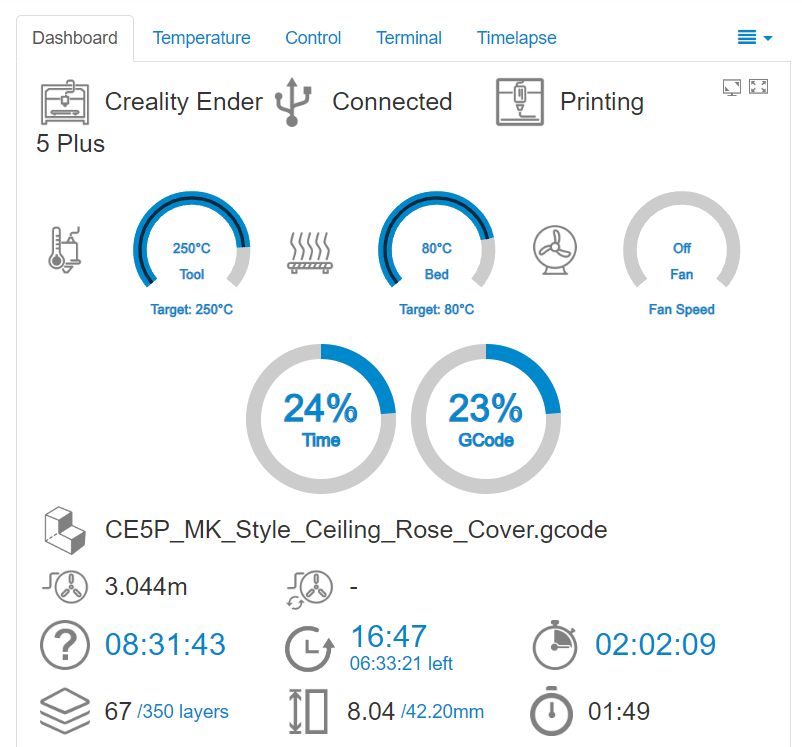

1. Melting Temperature: The melting temperature for ASA filament is typically around 230-250°C. It is important to maintain a consistent temperature throughout the printing process to ensure quality prints.

2. Filament Diameter: The diameter of ASA filament is usually 1.75mm or 3mm, but it can vary depending on the manufacturer.

3. Print Bed Temperature: The recommended print bed temperature for ASA filament is around 80-100°C. This is necessary to ensure good adhesion to the print bed.

4. Cooling: ASA filament requires some cooling during the printing process to prevent warping and improve dimensional stability.

5. Tensile Strength: ASA filament has a high tensile strength of around 45-60 MPa, which means it can withstand a lot of stress without breaking.

6. Flexural Strength: ASA filament also has a high flexural strength of around 60-80 MPa, which means it can bend and resist deformation without breaking.

7. Impact Strength: ASA filament has excellent impact strength, making it a good choice for parts that will be subjected to shock or vibration.

8. UV Resistance: ASA filament is highly resistant to UV radiation, which means it can be used for outdoor applications without degradation or yellowing.

9. Chemical Resistance: ASA filament is resistant to a wide range of chemicals, making it suitable for use in harsh environments.

10. Post-processing: ASA filament can be sanded, painted, and glued. It can also be annealed to improve its mechanical properties, but this requires special equipment and expertise.

As I continued to learn about 3D printing, I became more and more interested in the potential of ASA. I was amazed by the properties of this material and how it could be used to create functional parts for a variety of applications. I knew that I wanted to learn more about ASA and how to use it to its full potential.

I began to research ASA and 3D printing technology. I learned about the different types of 3D printers and the various methods of printing with ASA. I also learned about the different software programs that are available to help design and print 3D objects.

I was amazed by the possibilities of what I could create with ASA. I knew that I wanted to learn more about this amazing material and how to use it to its full potential. I continues to research and learn about ASA and 3D printing technology so that I can share my knowledge with others.

3D printed ASA is an amazing material with limitless potential. I urge you to learn more about this material and how to use it to its full potential.

Latest Articles

About Us

All Rights Reserved | Mitchell and Son Additive Manufacturing Ltd | Registered Company in England and Wales | Company Number : 12038697

| Public Liability Insurance no. 14615097

Insurer: AXA XL