HP PA12 Nylon 3D Printing Material UK | Strong & Functional Nylon Parts

PA12 nylon material ideal for strong, durable additive manufacturing parts — excellent for functional, load‑bearing applications.

Why This Material Has Quietly Become the Backbone of Industrial 3D Printing

When we talk about HP PA12 Nylon, we are not talking about a hobby material, a prototype-only plastic, or something that exists purely for visual models. This is an engineering-grade thermoplastic that has earned its place in real production environments. It is most commonly associated with HP Multi Jet Fusion (MJF), and there is a very good reason for that. PA12, or Polyamide 12, offers a balance of strength, flexibility, chemical resistance, and dimensional stability that few materials can genuinely compete with in additive manufacturing. What makes HP PA12 Nylon stand out is not just its raw performance figures, but the consistency and predictability of those figures when parts are produced at scale. In real-world manufacturing, repeatability matters just as much as strength, and this is where PA12 excels. Parts printed today will behave the same as parts printed six months from now, assuming the same process parameters. That reliability is what allows engineers, maintenance teams, and manufacturers to treat 3D printing not as an experiment, but as a dependable production tool.

From a material science perspective, PA12 sits in a very sweet spot. It is tougher than PLA, more dimensionally stable than ABS, and far less temperamental than high-end composites. It does not warp aggressively, it does not crack under modest impact, and it does not degrade rapidly under normal environmental exposure. For businesses looking to replace injection-moulded nylon parts in low-to-medium volumes, HP PA12 Nylon becomes an obvious candidate. It allows parts to be manufactured on demand, without tooling costs, while still delivering mechanical properties that are close enough to traditional moulded nylon to be trusted in service. This is precisely why you now see PA12 parts inside industrial machinery, automotive interiors, medical housings, jigs, fixtures, and enclosures that operate daily without anyone ever realising they are 3D printed.

What Makes HP PA12 Nylon Unique Compared to Other 3D Printing Materials

The uniqueness of HP PA12 Nylon lies in how balanced it is. Many materials are strong but brittle, flexible but weak, or stable but difficult to process. PA12 manages to avoid most of these compromises. Mechanically, it offers high tensile strength while still retaining a degree of elongation at break. This means it can absorb impact and vibration rather than cracking suddenly. That characteristic alone makes it extremely valuable for moving assemblies, clips, housings, and load-bearing brackets. Unlike brittle plastics, PA12 does not punish minor design mistakes. It has a forgiving nature that allows parts to survive in imperfect real-world conditions.

Thermally, PA12 performs reliably across a wide operating range. It does not soften at low temperatures, nor does it creep excessively under moderate heat. Its thermal stability is one of the reasons it is used for components inside enclosures, near motors, or in environments where ambient temperatures fluctuate. Chemically, PA12 resists oils, fuels, greases, and many solvents. This makes it particularly well-suited for industrial maintenance parts, automotive components, and tooling that may come into contact with harsh substances during normal use. In contrast, many consumer-grade filaments will swell, weaken, or degrade when exposed to these environments.

Another defining characteristic of HP PA12 Nylon is its isotropic strength when printed using Multi Jet Fusion. Traditional FDM printing produces parts that are weaker along layer lines. PA12 printed via MJF does not suffer from this limitation to the same extent. Strength is far more uniform in all directions, which gives engineers confidence to design parts without having to “cheat” around layer orientation. This isotropy is one of the key reasons PA12 has moved beyond prototyping and into production. You can design for function, not for printer limitations, and that changes the entire engineering conversation.

How 3D Printing with HP PA12 Nylon Benefits Manufacturing and Industry

The biggest benefit of 3D printing with HP PA12 Nylon is speed without compromise. Traditional manufacturing methods such as injection moulding are excellent for high volumes, but they are slow and expensive to set up. Tooling alone can cost thousands, sometimes tens of thousands, before a single part is produced. PA12 eliminates that barrier entirely. A digital file becomes a physical component in days, sometimes hours. This changes how companies approach spares, repairs, and product development. Instead of holding expensive stock or waiting weeks for parts, businesses can produce exactly what they need, when they need it.

For maintenance and operations teams, this is transformative. A broken bracket, clip, or housing can shut down equipment that costs tens of thousands per hour in lost productivity. With HP PA12 Nylon, those parts can be recreated, improved, and installed rapidly. In many cases, the printed replacement is not just a copy but an upgrade. Wall thickness can be increased, stress points reinforced, and design flaws eliminated, all without changing manufacturing infrastructure. This ability to iterate quickly is something traditional manufacturing simply cannot match.

From a cost perspective, PA12 also makes sense for short runs and bespoke components. Producing 5, 50, or even 500 parts becomes economically viable without sacrificing material quality. For small manufacturers and specialised industries, this opens doors that were previously closed. You no longer need to justify large batch sizes to make production “worth it.” The economics shift in favour of flexibility, responsiveness, and customisation, which aligns perfectly with modern manufacturing needs.

Technical Properties of HP PA12 Nylon (Engineering Overview)

HP PA12 Nylon is not popular by accident; its technical performance supports its reputation. Typical material properties include a tensile strength in the region of 48–50 MPa, with elongation at break around 20%. This combination provides both strength and toughness, allowing parts to withstand mechanical stress without sudden failure. The Young’s modulus typically sits around 1700 MPa, indicating a material that is stiff enough for structural use while still retaining resilience.

Impact resistance is another key area where PA12 shines. It performs well under repeated loading and vibration, making it suitable for clips, snap-fit assemblies, and moving parts. The heat deflection temperature is generally around 95–100°C, which is sufficient for most industrial and automotive interior applications. While it is not designed for extreme high-temperature environments, it comfortably handles the majority of real-world operating conditions encountered in machinery and enclosures.

Dimensional accuracy is also a standout feature. HP MJF-produced PA12 parts maintain tight tolerances, often within ±0.2 mm, depending on geometry. This level of precision allows parts to fit together reliably without excessive post-processing. Surface finish, while slightly matte and grainy by default, is consistent and can be improved through bead blasting, dyeing, or coating if required. These technical characteristics combine to make PA12 one of the most versatile and dependable materials currently available in additive manufacturing.

Real-World Application: Industrial Machinery Replacement Components

A very common real-world application for HP PA12 Nylon is the replacement of obsolete or unavailable industrial components. Many factories operate machinery that is decades old, where spare parts are no longer manufactured or are prohibitively expensive. PA12 allows these parts to be reverse-engineered, improved, and put back into service quickly. Housings, guards, cable clips, sensor mounts, and brackets are all ideal candidates for this material.

In one typical scenario, a small but critical plastic component fails, halting production. Injection moulding a replacement is unrealistic due to cost and lead time. Using HP PA12 Nylon, the part can be recreated from a damaged sample, strengthened where necessary, and printed with excellent dimensional accuracy. The result is a functional replacement that performs as well as, or better than, the original. This approach saves money, reduces downtime, and extends the life of expensive machinery without major capital investment.

Design Freedom with HP PA12 Nylon

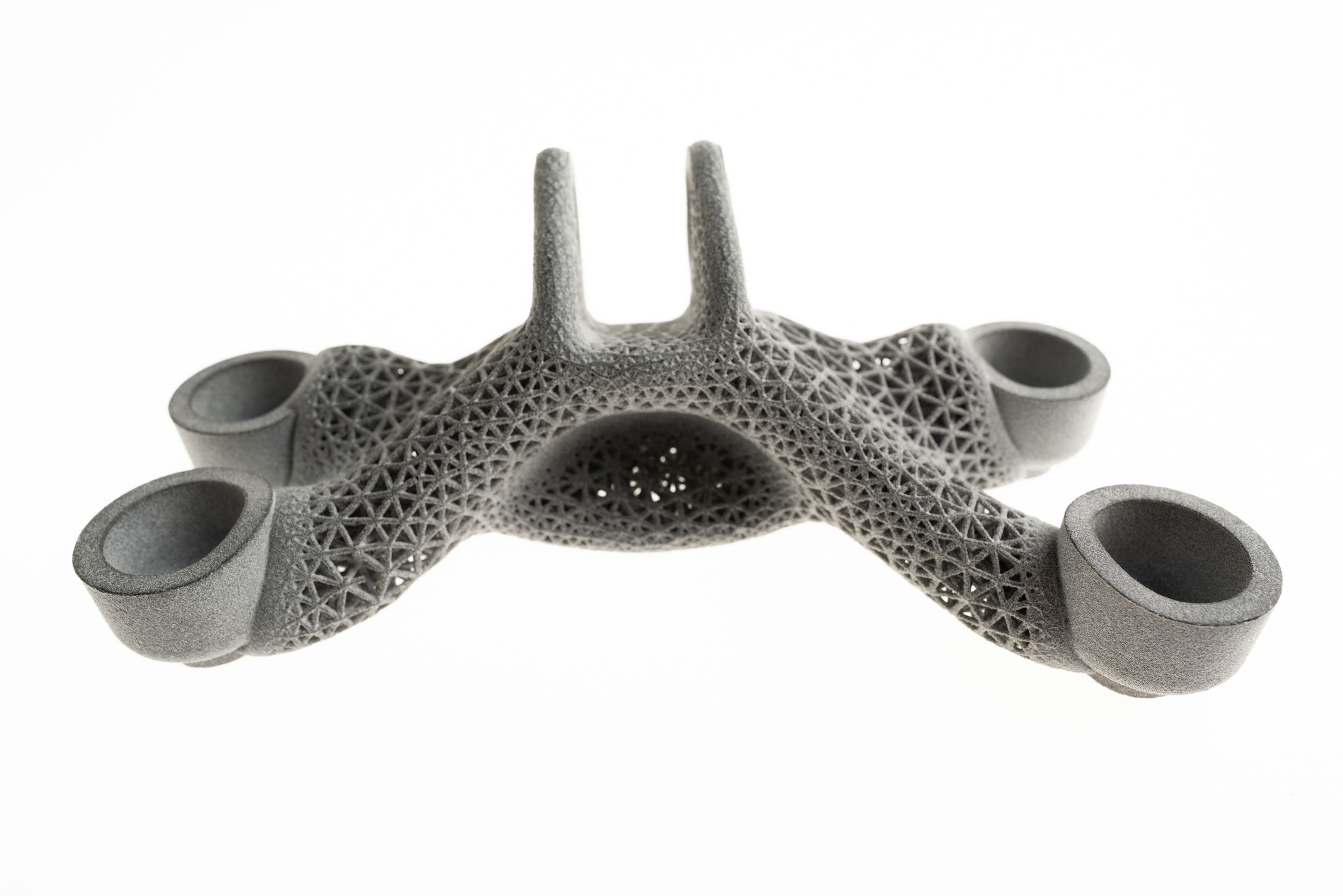

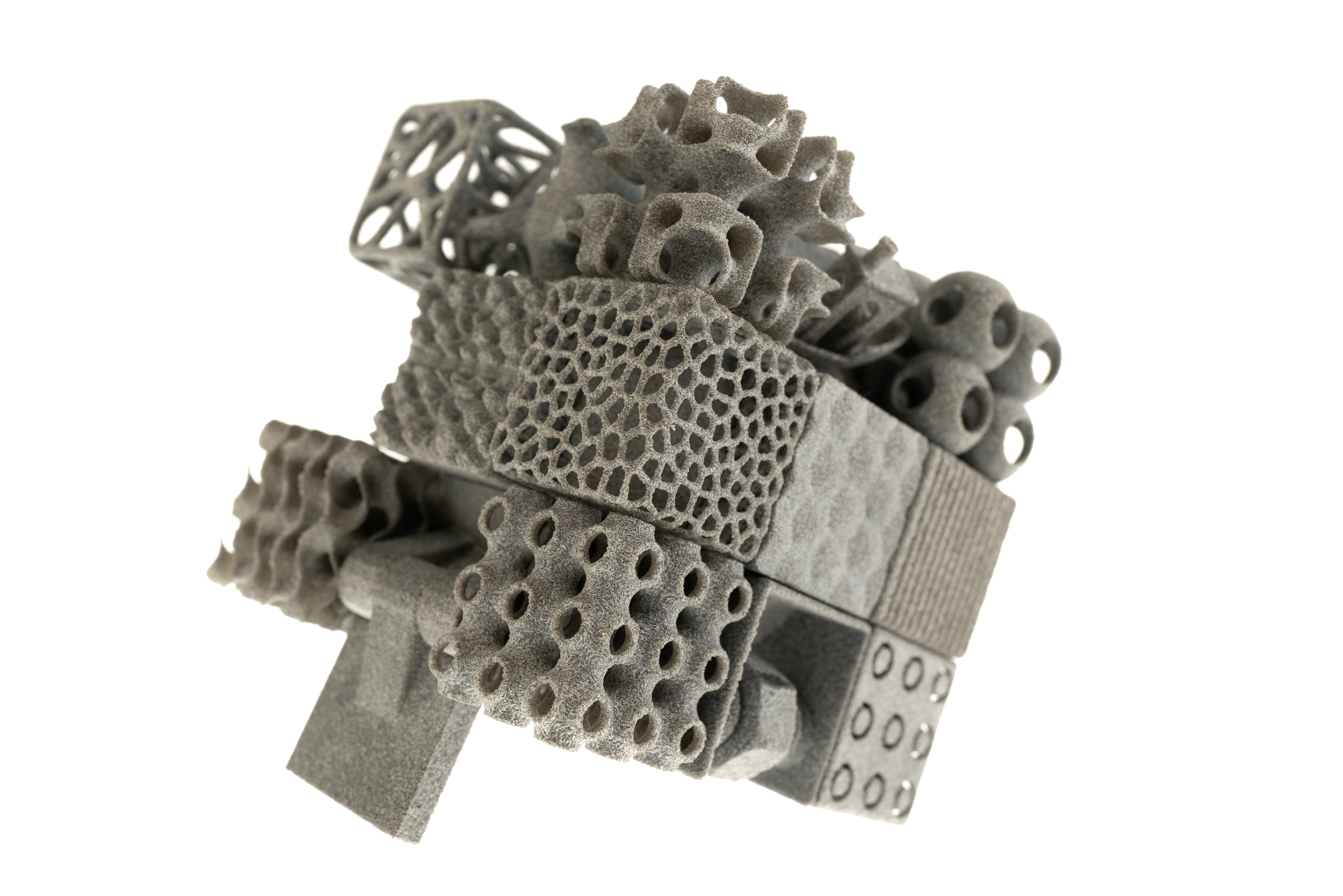

One of the less obvious advantages of PA12 is the design freedom it offers. Internal channels, complex geometries, lattice structures, and integrated assemblies can be produced in a single print. These designs would be impossible or prohibitively expensive using traditional manufacturing methods. Engineers can optimise parts for weight, airflow, or strength without worrying about tooling constraints. This leads to smarter, more efficient components that are tailored precisely to their application.

Because PA12 handles complex geometries well, it is often used for jigs and fixtures in manufacturing environments. These tools need to be strong, dimensionally stable, and customised to specific tasks. PA12 delivers all of this while allowing rapid iteration when processes change. Instead of redesigning tooling from scratch, modifications can be made digitally and implemented almost immediately.

FAQs

Is Hp Pa12 Nylon suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Hp Pa12 Nylon for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.