PLA 3D Printing Material UK | Easy & Eco‑Friendly Prints

PLA filament — user‑friendly, biodegradable 3D printing material ideal for prototypes, models and non‑structural parts

What Makes PLA Unique

PLA is unique because it sits at the intersection of accessibility, consistency, and sustainability. When you heat PLA, it melts cleanly and flows in a very controlled manner. That flow characteristic makes layer adhesion reliable without needing excessive heat or pressure. This is why PLA prints so well on open-frame machines and budget printers, yet still performs consistently on industrial-grade systems.

One of PLA’s most distinctive characteristics is its low glass transition temperature, typically around 55–65 °C. This means it transitions from rigid to rubbery at relatively low heat compared to ABS or Nylon. While that limits PLA in high-temperature environments, it is precisely what makes it so easy to print. The filament does not need aggressive bed temperatures or enclosed chambers to prevent warping. As a result, dimensional accuracy is excellent, especially on parts with sharp corners, fine text, or thin walls.

Another unique advantage of PLA is its surface finish. Straight off the printer, PLA produces a clean, crisp finish with well-defined layer lines that are far less pronounced than many other materials. This makes it ideal for visual prototypes, presentation models, and consumer-facing components where appearance matters. In many cases, PLA parts can be used as-printed without sanding, priming, or post-processing.

PLA is also chemically stable and largely odour-free during printing. That may sound trivial, but in real-world environments such as offices, classrooms, clinics, or studios, this matters. You can print PLA all day without filling the room with fumes, which is not something you can say about ABS or some nylons.

Finally, PLA’s renewability gives it a unique position in modern manufacturing. While “biodegradable” is often misunderstood, PLA’s plant-based origin reduces reliance on fossil fuels. For short-life products, prototypes, and educational use, this is a meaningful advantage.

Why PLA Works So Well for 3D Printing

PLA works well for 3D printing because it is forgiving by nature. It has a wide processing window, typically printing between 190 °C and 220 °C, depending on formulation. That tolerance means small variations in nozzle temperature, cooling, or extrusion rate rarely result in catastrophic failures. For businesses and individuals alike, that translates into fewer failed prints and less wasted time.

Warping is one of the biggest challenges in fused-filament fabrication. PLA’s low thermal contraction significantly reduces internal stresses as the part cools. This allows large flat surfaces, sharp edges, and long straight features to remain flat and true without lifting from the bed. In practical terms, it means you can print functional jigs, brackets, housings, and fixtures without designing in elaborate warping compensation.

Layer adhesion in PLA is strong when printed correctly. While it is not as impact-resistant as ABS or PETG, the bond between layers is consistent and predictable. This makes PLA suitable for parts subjected to light mechanical loads, especially when printed with higher infill or increased wall thickness.

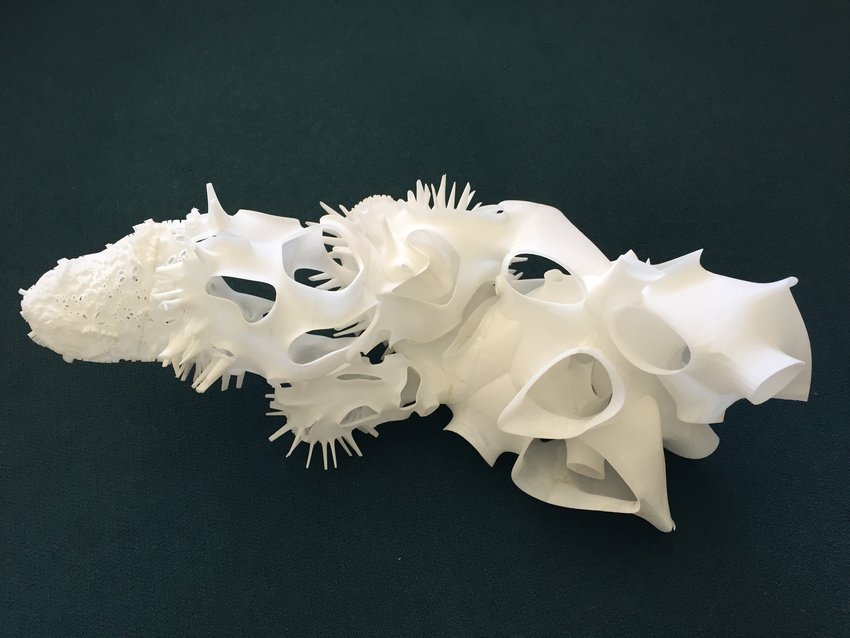

Cooling behaviour is another reason PLA excels. It responds exceptionally well to part cooling fans, which allows for crisp overhangs, bridges, and fine details. That capability is why PLA is often the material of choice for figurines, architectural models, educational aids, and product mock-ups.

In short, PLA removes barriers. It allows designers, engineers, and entrepreneurs to focus on design intent, not constant printer calibration.

Why PLA Works So Well for 3D Printing

PLA works well for 3D printing because it is forgiving by nature. It has a wide processing window, typically printing between 190 °C and 220 °C, depending on formulation. That tolerance means small variations in nozzle temperature, cooling, or extrusion rate rarely result in catastrophic failures. For businesses and individuals alike, that translates into fewer failed prints and less wasted time.

Warping is one of the biggest challenges in fused-filament fabrication. PLA’s low thermal contraction significantly reduces internal stresses as the part cools. This allows large flat surfaces, sharp edges, and long straight features to remain flat and true without lifting from the bed. In practical terms, it means you can print functional jigs, brackets, housings, and fixtures without designing in elaborate warping compensation.

Layer adhesion in PLA is strong when printed correctly. While it is not as impact-resistant as ABS or PETG, the bond between layers is consistent and predictable. This makes PLA suitable for parts subjected to light mechanical loads, especially when printed with higher infill or increased wall thickness.

Cooling behaviour is another reason PLA excels. It responds exceptionally well to part cooling fans, which allows for crisp overhangs, bridges, and fine details. That capability is why PLA is often the material of choice for figurines, architectural models, educational aids, and product mock-ups.

In short, PLA removes barriers. It allows designers, engineers, and entrepreneurs to focus on design intent, not constant printer calibration.

How PLA Benefits People and Businesses

From a business perspective, PLA reduces risk and cost. When prototyping a new product, time is money. PLA allows rapid iteration without expensive tooling or long lead times. You can design, print, test, modify, and reprint in a single day. That speed fundamentally changes how products are developed.

For small manufacturers and local businesses, PLA enables short-run production that would otherwise be economically impossible. Injection moulding requires tooling costs that often run into thousands of pounds. PLA-based 3D printing removes that barrier entirely. Low-volume components, custom fixtures, bespoke housings, and replacement parts can be produced on demand.

For individuals, PLA democratises manufacturing. Hobbyists, students, and inventors can turn ideas into physical objects without industrial infrastructure. That has enormous knock-on effects for education, entrepreneurship, and skills development.

PLA also benefits customers indirectly. Faster development cycles mean better products reach the market sooner. Customisation becomes viable. Niche requirements that would never justify traditional manufacturing suddenly become practical.

PLA in Real-World Applications

PLA is widely used in prototyping, education, packaging, medical modelling, and consumer products. In education, it is the default material for teaching design and engineering principles. Students can physically test geometry, tolerances, and assembly concepts.

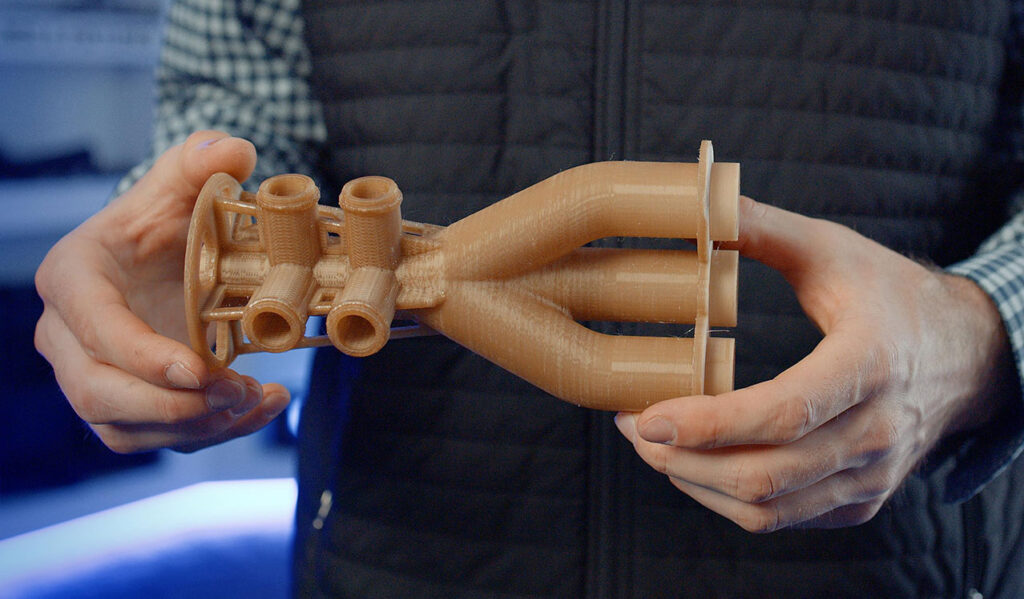

In healthcare, PLA is commonly used for anatomical models, surgical planning aids, and orthotic prototypes. Its dimensional accuracy and ease of printing make it ideal for translating scan data into tangible models.

In packaging design, PLA allows rapid evaluation of form, ergonomics, and branding before committing to tooling. Consumer goods companies routinely use PLA for proof-of-concept housings and display models.

PLA is also heavily used in jigs and fixtures for light-duty workshop applications. Drill guides, alignment tools, cable clips, and assembly aids are all common PLA use cases when temperature exposure is controlled.

The Limits of PLA

PLA is not an engineering plastic in the traditional sense, and it is important to be clear about that. Its heat resistance is limited, with deformation beginning around 55–60 °C. Parts left in hot cars, near engines, or under sustained load in warm environments will deform.

Impact resistance is moderate. PLA is stiff and strong under compression but can be brittle under sudden shock. For moving parts, outdoor applications, or high-stress components, alternative materials are usually more appropriate.

That said, understanding PLA’s limits is not a weakness. It is simply good engineering practice. When used within its design envelope, PLA performs exceptionally well.

Technical Details of PLA Filament:

Material type: Thermoplastic biopolymer

Density: ~1.24 g/cm³

Nozzle temperature: 190–220 °C

Bed temperature: 20–60 °C (often optional)

Glass transition temperature: ~55–65 °C

Tensile strength: 50–70 MPa

Young’s modulus: ~3.5 GPa

Elongation at break: 4–10%

Shrinkage: Very low

Odour during printing: Minimal

FAQs

Is Pla suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Pla for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.