Resin 3D Printing Material UK | High Detail & Smooth Finish

Resin materials for high‑resolution 3D prints with fine detail — ideal for visual prototypes and presentation parts.

Why Resin Printing Is Fundamentally Different

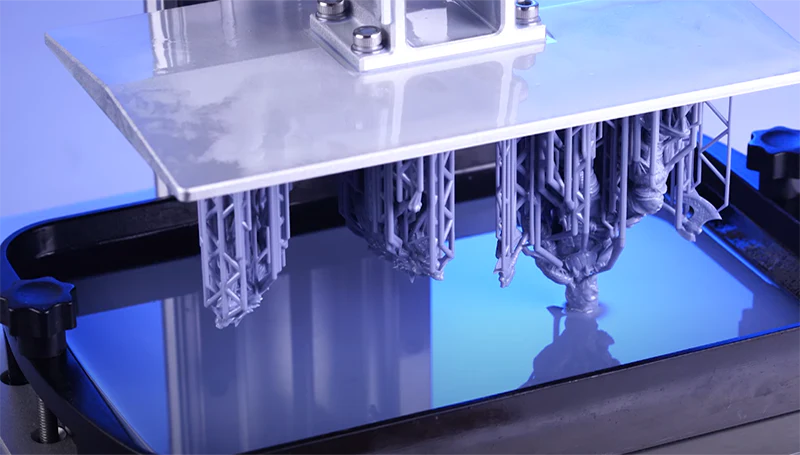

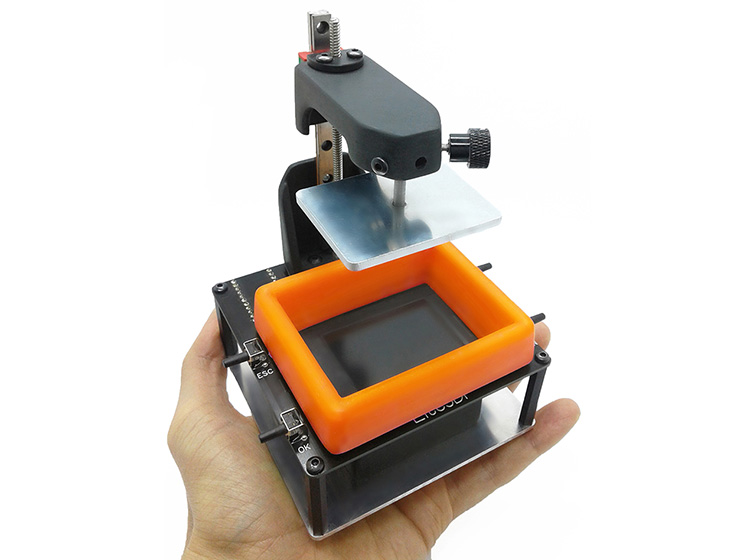

The defining characteristic of 3D printed resin is how the material forms. Resin begins life as a liquid, stored in a vat, and only becomes solid when UV light triggers a chemical reaction known as photopolymerisation. Each layer is cured as a complete surface rather than a single extruded line, which is why resin parts achieve exceptional dimensional accuracy and surface smoothness.

Because there is no nozzle pushing molten plastic, resin printing avoids many of the mechanical limitations found in filament printing. There is no nozzle diameter limiting resolution, no stringing between moves, and no visible extrusion paths. This allows resin printers to routinely achieve layer heights of 25–50 microns, with XY resolution governed by pixel size rather than nozzle width. The result is parts that look manufactured rather than printed.

Another critical difference is isotropy. While resin parts are still layered, the chemical bonding between layers is often stronger and more consistent than filament prints, particularly when properly post-cured. This leads to more predictable mechanical behaviour, which is essential when producing test components, snap-fits, or mating parts.

From a business standpoint, resin printing allows low-volume, high-precision manufacturing without the tooling costs associated with injection moulding. For many applications—especially short-run production, validation parts, and discontinued components—resin printing is not a compromise; it is the optimal solution. You are trading tooling cost and lead time for digital control and immediate manufacturability.

This is why resin printing continues to expand into regulated and industrial environments. It is not because it is cheaper per unit at scale—it often is not—but because it removes friction from design iteration, replacement manufacturing, and precision fabrication.

The Materials Science Behind Resin

Not all resins are the same, and this is where misconceptions often arise. Early consumer resins were brittle, UV-sensitive, and unsuitable for anything beyond visual models. Modern engineering resins, however, are a different category entirely.

Today’s resins are formulated to achieve specific mechanical, thermal, and chemical properties. You can select resins that are:

High-strength and impact-resistant

Heat-resistant (up to 230 °C HDT in some formulations)

Flexible or elastomeric

Rigid and glass-filled

Electrically insulating

Biocompatible or chemically resistant

Typical technical properties for engineering resin include:

Tensile strength: 40–80 MPa

Elongation at break: 5–50% depending on formulation

Shore hardness: 70D–90D (rigid resins)

Heat deflection temperature: 60–230 °C

Shrinkage: typically <0.5%

What matters in practice is resin selection based on use case, not marketing names. A resin used for dental splints has very different chemistry from one designed for under-bonnet automotive components. Understanding the operating environment—heat, UV exposure, mechanical load, chemicals—is essential before choosing resin.

When used correctly, resin is not fragile. It is precise. Fragility only occurs when the wrong resin is chosen for the job or when post-curing is neglected. Proper curing completes the polymer chain, increasing strength, heat resistance, and dimensional stability. This is why professional resin workflows always include washing, drying, and controlled UV curing as standard practice.

How Resin Printing Benefits Real Manufacturing

The biggest benefit of 3D printed resin is time-to-solution. Traditional manufacturing assumes volume. Resin printing assumes specificity. If a component is obsolete, unavailable, or requires modification, resin allows it to be recreated in days rather than months.

This is particularly valuable in maintenance, restoration, and specialist engineering. Instead of redesigning assemblies around unavailable parts, resin printing enables reverse engineering and direct replacement. This reduces downtime, avoids redesign risk, and preserves original system behaviour.

For small businesses and engineering teams, resin printing also enables functional prototyping without compromise. Design validation can be done using production-grade geometry rather than simplified test shapes. This leads to better decisions earlier in the development cycle.

In sectors like electronics, resin printing excels at enclosures, mounts, and fixtures where tolerance stacking matters. Snap-fits behave as designed. Screw bosses align correctly. Cable channels and airflow paths print cleanly without support scarring where it matters.

In my experience, the real value of resin printing is not in novelty but in problem-solving. It fills the gap between CAD intent and physical reality with minimal distortion. That reliability is what makes it commercially valuable.

Accuracy, Surface Finish, and Professional Output

Surface finish is not cosmetic—it is functional. In resin printing, smooth surfaces reduce friction, improve sealing, and eliminate stress risers. This is why resin parts are often used directly without machining in applications where filament prints would require secondary finishing.

Dimensional accuracy is equally important. Resin printers routinely achieve tolerances of ±0.05 mm under controlled conditions. This allows parts to be designed with confidence rather than compensation. Threads print cleanly. Fine lettering remains legible. Thin walls retain structural integrity.

This level of fidelity changes how products are designed. Instead of simplifying geometry to suit manufacturing, resin printing allows geometry to exist as intended. That freedom is especially valuable in medical, dental, and precision engineering contexts.

Real-World Applications That Actually Matter

Resin printing is not theoretical—it is embedded in real workflows today. Dental aligners, surgical guides, hearing aid shells, inspection gauges, electrical housings, camera components, and aerospace fixtures are all routinely produced using resin.

A common real-world application I encounter is replacement components for legacy systems. When spares are no longer available and tooling costs are unjustifiable, resin printing offers a direct, economical alternative. Parts can be redesigned slightly to improve durability while retaining original fit and function.

Another practical use is short-run production. Instead of committing to thousands of moulded parts, businesses can produce tens or hundreds of resin components with consistent quality and zero tooling investment. That flexibility is often the difference between a viable product and a shelved idea.

3D printed resin is not a replacement for all manufacturing—it is a precision tool. Used properly, it delivers accuracy, speed, and problem-solving capability that traditional processes struggle to match at low volumes. When customers understand what resin printing actually is—and what it is not—it becomes one of the most powerful tools available in modern digital manufacturing.

FAQs

Is Resin suitable for outdoor use?

It depends on UV exposure and heat. Tell us the environment and we’ll advise the best material.

Can you print Resin for functional parts?

Yes. If you share the part purpose and any load/heat details, we’ll confirm the best settings and material choice.