Stereolithography (SLA)

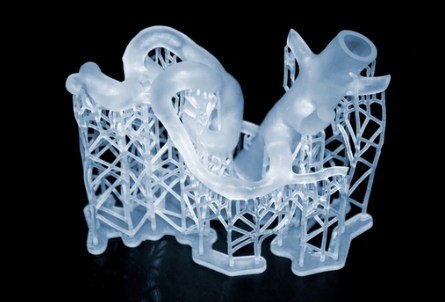

Stereolithography is a 3D Printing process which uses a computer-controlled moving laser beam, pre-programmed using CAM/CAD software. Stereolithography (SL) is an industrial 3D printing process used to create concept models, cosmetic - rapid prototypes, and complex parts with intricate geometries in as fast as 1 day.

The technology was invented in 1986 by Charles W. Hull, who co-founded 3D Systems Corp. The first stereolithography machine was capable of creating small two-dimensional shapes. However, over the years the technology has evolved and progressed to where it is today.

Stereolithography works by using a photopolymer resin that is cured by exposure to light. The machine traces out the desired geometry layer by layer using a computer-controlled moving laser beam. The beam is directed by mirrors that are positioned around the build platform.

The build platform is lowered into the vat of photopolymer resin after each layer is cured. This process is repeated until the desired geometry is achieved.

The advantage of stereolithography is that it can create parts with very intricate geometries that would be difficult or impossible to create using traditional manufacturing methods. Additionally, the lead time for stereolithography is much shorter than traditional methods such as milling or machining.

The downside of stereolithography is that it is a relatively expensive technology. Additionally, the material properties of the parts that are produced are not as good as those produced using traditional methods.

Overall, stereolithography is a versatile and powerful technology that has a wide range of applications in industry and research.

How it works? Stereolithography, or SLA 3D printing, is a type of additive manufacturing technology used for creating models, prototypes, patterns, and production parts. SLA printing works by first positioning the build platform in the tank of liquid photopolymer, at a distance of one layer height for the surface of the liquid. A UV laser creates the next layer by selectively curing and solidifying the photopolymer resin. The build platform is then lowered by one layer thickness, and the next cross-section is drawn. This process is repeated until the build is complete.

SLA is an acronym for “stereolithography apparatus” or “stereo lithographic apparatus.” It was invented in 1986 by Chuck Hull, who later founded 3D Systems Corporation. The patent for stereolithography (U.S. Patent 4,575,330) was issued in 1986 and expires in 2004.

The key advantage of stereolithography is its accuracy. SLA is capable of producing parts with very fine features and detail, as well as smooth surfaces. Additionally, SLA is one of the fastest additive manufacturing technologies, with some machines capable of printing a layer in as little as 12 seconds.

Resin 3D printing i s often used for creating prototypes and models, as well as for low-volume production. Applications for SLA parts include investment casting patterns, medical devices, and eyewear.

Stereolithography is an amazing tool that can be used to create accurate models of just about anything. Whether you need a prototype for a new product or a 3D model of a patient's anatomy, stereolithography can get the job done quickly and accurately.

This technology is especially useful for pre-planning and implant design. With stereolithography, you can create a 3D model of the patient's anatomy and use it to plan the surgery in advance. This ensures that everything goes according to plan and that the implant fits perfectly.

Stereolithography is also great for creating concept models and scale models. If you need to create a prototype of a new product, stereolithography can help you do it quickly and accurately. And if you need to create a scale model of something, stereolithography can create a perfect replica.

No matter what your needs are, stereolithography is a great tool that can help you achieve your goals. So if you need to create a accurate model of something, don't hesitate to use stereolithography.

Stereolithography (SLA) – Precision Engineered 3D Printing

Industrial‑grade resin 3D printing for high‑precision prototypes and complex parts

Introduction

Stereolithography (SLA) stands at the forefront of additive manufacturing for parts that demand ultra‑fine detail, exceptional surface finish and rapid turnaround. At Mitchell & Son, SLA isn’t just a technology — it’s a tool that empowers engineers and manufacturers to push the boundaries of design, reduce development cycles, and bring high‑quality concepts to life with confidence.

mitchellsson.co.uk

What is SLA?

SLA — short for Stereolithography Apparatus — is a photopolymer‑based 3D printing technology that creates parts by curing liquid resin with a computer‑controlled UV laser, layer by layer, according to your CAD model. Each cross‑section is meticulously traced by the laser into a vat of liquid resin, solidifying it almost instantly. This process repeats until your part is complete.

mitchellsson.co.uk

Where traditional manufacturing methods fall short — like organic curves or internal channels — SLA excels. The result: parts with tight tolerances, smooth surfaces, and complex geometry that are virtually impossible to produce through subtractive means.

Technical Specifications (SLA)

To meet demanding engineering requirements, here’s how SLA performs on key parameters:

▸ Resolution & Detail:

• Minimum feature size: down to 0.025 mm on certain industrial SLA systems

• Layer thickness: 25–100 microns for controlled surface smoothness

• Exceptional dimensional accuracy for small features

▸ Materials:

• Rigid engineering resins

• Tough & durable photopolymers

• UV‑stable, transparent & castable resins

▸ Machine Output:

• Build volumes vary depending on platform (bench to industrial scale)

• Capable of stacking multiple small, highly detailed parts in a single run

▸ Surface Quality:

• SLA delivers the best surface finish among polymer 3D printing technologies, ideal when you need parts right off the machine with minimal post‑processing.

Wikipedia

These specifications make SLA ideal for precision engineering applications where accuracy, detail and surface finish matter most.

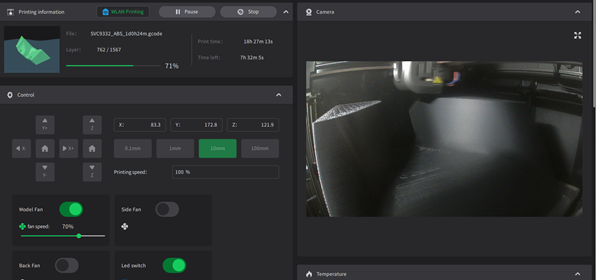

How SLA Works – Step by Step

CAD to SLA Conversion:

Your CAD file is sliced into hundreds to thousands of thin 2D layers.

UV Laser Cures Resin:

A focused laser cures each layer of resin once the build platform dips into a vat of liquid photopolymer.

Layer‑by‑Layer Build:

After each layer is cured, the platform moves downwards, allowing new resin to flow, and the next layer is solidified.

Post‑Processing:

Parts are rinsed, cured with additional UV exposure, and optionally finished (sanding, coating).

This method produces parts with minimal layer‑stair stepping and smooth surfaces, which is a game‑changer for engineering prototypes and visual models alike.

mitchellsson.co.uk

Real‑World Engineering Applications

Precision Prototypes & Functional Verification

Engineers use SLA for form and fit testing before committing to expensive tooling. With its fine detail and tight tolerances, SLA parts can be used for:

• Functional prototypes that mimic end‑use geometries

• Snap fits and assembly features for design validation

• Part verification against performance requirements

This reduces costly iterations and accelerates product development cycles.

Tooling, Jigs & Fixtures

Highly accurate SLA parts can serve as:

• Master patterns for injection moulding

• Low‑volume tooling inserts

• Custom assembly fixtures

Manufacturers reduce time to production and enhance quality control without traditional machining expenses.

Wikipedia

Medical Devices & Custom Components

Because of its precision, SLA is widely used in medical prototyping — from surgical guides to anatomical models. SLA parts can be produced quickly, aiding design engineers and clinicians with tangible references for design refinement.

Why SLA Appeals to Engineering & Manufacturing

✔ Exceptional precision and resolution for detailed parts

✔ Faster lead times than traditional machining or tooling

✔ Perfect for complex geometries and organic shapes

✔ Enhances iterative design and reduces development risk

For sectors that demand engineering excellence — aerospace, automotive, healthcare and more — SLA provides a reliable, consistent, and production‑ready solution for prototyping and low‑volume parts.

Summary

SLA 3D printing stands as a powerful precision manufacturing technology. Its ability to deliver smooth, detailed, and accurate parts makes it a staple for engineering teams seeking to shorten lead times, reduce costs and push innovation forward. From concept prototypes to functional engineering parts, SLA is a go‑to choice when quality and detail matter.