Threaded Inserts in 3D Printed Products

Benefits of Threaded Inserts in 3D Printed Products

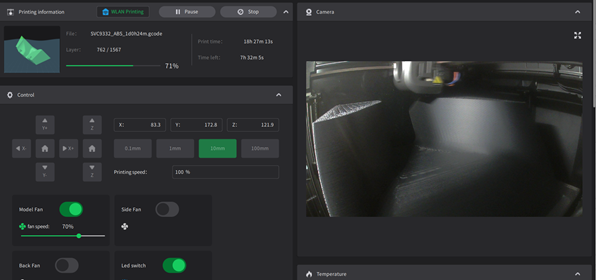

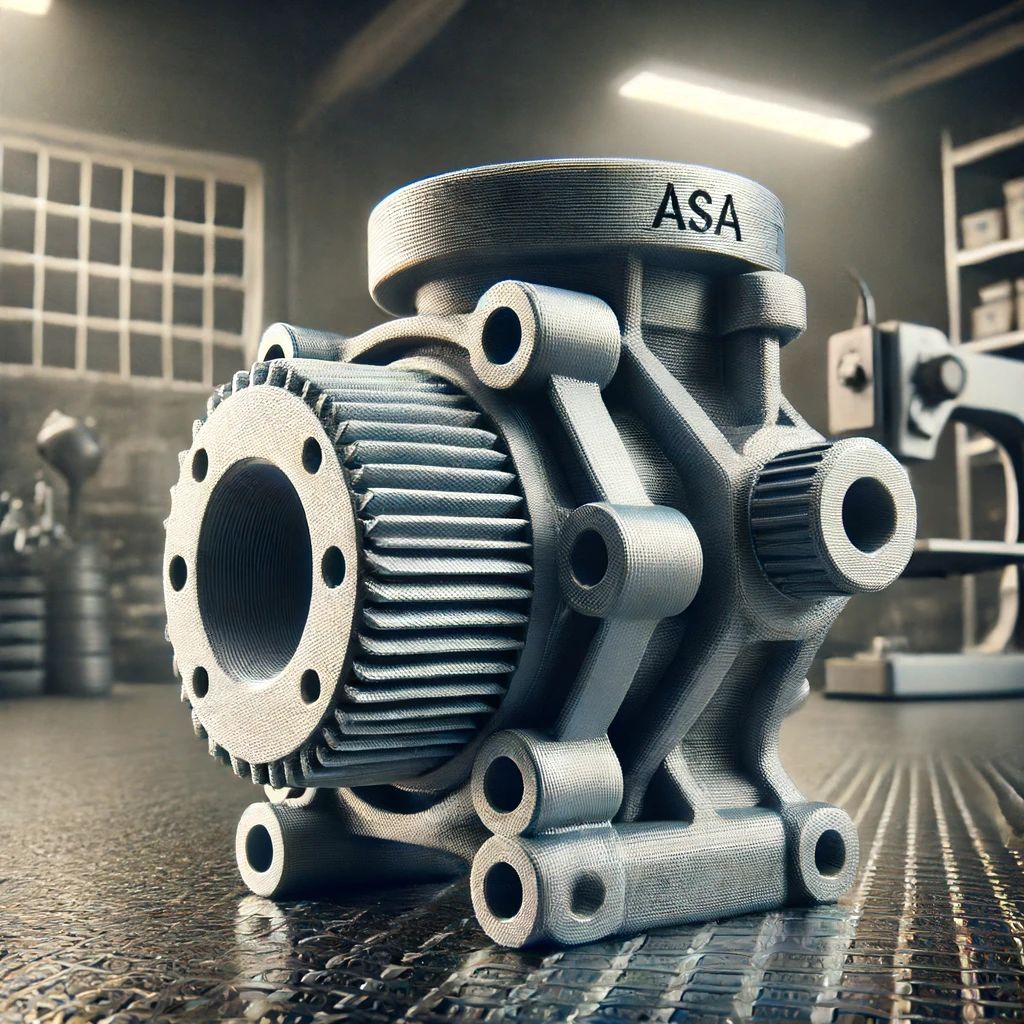

It is my own personal assumption that we have turned the corner when it comes to 3D Printing products because we have moved away from purely printing prototypes to printing functional parts in a range of composite plastics, resins, and metals.

One of the shortfalls of printing a functional part in plastic is that it can wear very quickly especially if you are producing parts that need to or have a screw fixture.

If you are going to screw the part together and then never undo that screw for the life of the product then that is great but what if you have a product that contains electronic or mechanical parts that may need maintenance and therefore will require a fairly regular unscrewing to open and then screwing it to close again.

It would not take to long to wear out and have to be replaced, especially if the locking screws are metal.

Now that we are moving to more functional 3D Printed parts, I will put to you the reasons why designing and adding metal inserts would be a massive advantage to your 3D Printed assembly.

- Increased Strength: Threaded inserts provide a more robust threading compared to directly tapping the 3D printed material.

- Durability: Metal inserts are more wear-resistant, prolonging the life of the threaded connection.

- Heat Resistance: Inserts are often made of metal, which can withstand higher temperatures than plastic.

- Ease of Assembly: Inserts simplify the assembly process by providing reliable and repeatable threads.

- Reusability: Threaded inserts allow for repeated assembly and disassembly without degrading the threads.

- Load Bearing: They can support higher loads compared to printed threads.

- Vibration Resistance: Inserts can resist vibrations better, preventing loosening in dynamic applications.

- Improved Precision: Achieve more precise threading tolerances than printing directly.

- Versatility: Available in various materials and sizes, suitable for different applications.

- Corrosion Resistance: Inserts made from stainless steel or brass offer excellent corrosion resistance.

- Ease of Installation: Can be installed using simple tools and methods like heat, ultrasonic, or press fitting.

- Enhanced Aesthetics: Provide a cleaner, more professional finish.

- Compatibility: Compatible with standard fasteners, allowing for integration with existing systems.

- Reduced Wear on Fasteners: Fasteners experience less wear when used with metal inserts.

- High Torque Resistance: Can withstand higher torque applications without stripping.

- Chemical Resistance: Suitable for use in environments with harsh chemicals if made from the appropriate material.

- Flexibility in Design: Allows for the inclusion of metal threads in intricate designs that would be challenging to machine.

- Cost Efficiency: Reduces the need for expensive machining of threads.

- Customization: Can be tailored to specific design requirements and materials.

- Time Efficiency: Speeds up the prototyping process by eliminating the need for post-printing thread cutting.

When requiring the 3D Printed assembled part to have inserts fitted, bear in mind that the design must accommodate the insert.

The assumption must never be that an insert can be fitted to any 3D Printed Assembly without the designer making a provision for it to be added

Incorporating threaded inserts into 3D printed products offers an extensive array of benefits, significantly enhancing durability, functionality, and usability. Threaded inserts provide highly secure fastening points, which greatly improve the longevity and strength of threaded connections in 3D-printed components.

These inserts are essential in overcoming the inherent limitations of 3D printed materials, which are often less robust and wear-resistant than traditional materials. By integrating threaded inserts, the structural integrity of the printed parts is vastly increased, allowing them to withstand higher loads, resist wear and tear, and endure repeated assembly and disassembly without degradation.

Threaded inserts also offer improved heat and chemical resistance, making them suitable for a wider range of environments and applications.

They enable precise and repeatable thread creation, which is difficult to achieve with 3D printing alone. This precision ensures a perfect fit for fasteners, leading to smoother assembly processes and more reliable joints.

Furthermore, the inserts' compatibility with standard fasteners simplifies the design process, as they can easily be integrated into existing systems without the need for specialized components.