What’s the Best Plastic for Outdoor Use?

What’s the Best Plastic for Outdoor Use? Here’s What I Tell My Customers

So this comes up a lot — someone’s working on a project that’s going to live outside, and they want to know what plastic they should be using. Not all plastics are created equal, and if you get it wrong, it’s going to cost you in the long run.

Cracking, warping, fading — I’ve seen it all.

Let me break it down the way I’d explain it to anyone in the workshop or over a brew.

☀️ First Thing: UV Is the Real Enemy

A lot of people think plastic’s plastic — but some types go brittle in the sun. That’s UV exposure for you. You leave something out in the weather, and if it’s not the right material, it’ll start breaking down after a year or two.

So whenever someone says, “I want to make this for the garden” or “It’s going to sit in direct sun” — I steer them clear of standard ABS.

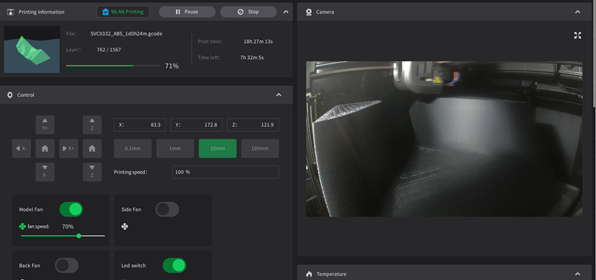

❌ Why ABS Is Not Great Outdoors

Now don’t get me wrong, ABS is a tough plastic. I use it for all sorts of indoor parts — brackets, housings, clips, you name it. It prints well, it’s strong, and it’s easy to post-process.

But — and it’s a big but — ABS doesn’t like the sun.

You leave it outdoors, and after a few seasons, it gets brittle. Starts to flake. You’ll think it’s fine one day, and the next, it just snaps under light pressure. That’s UV damage.

So what do I recommend instead?

✅ PETG – The Solid All-Rounder for Outdoor Use

PETG is usually my go-to for anything that’s going to live outside.

It’s basically a more weather-resistant cousin to ABS.

Still strong, still prints nicely, but it’s got better UV resistance and handles moisture better too.

Couple reasons I like PETG for outdoor use:

- Better UV resistance than ABS

- Glossy finish straight off the printer — looks more polished

- Less warping — so if you’re printing larger parts, it behaves better

I’ve used PETG to make outdoor brackets, signs, garden tool clips, and even replacement parts for greenhouses and sheds. Still holding up years later.

🪵 Other Options (If You Want to Get Fancy)

If someone wants to go a step up from PETG, there are a few other materials worth considering:

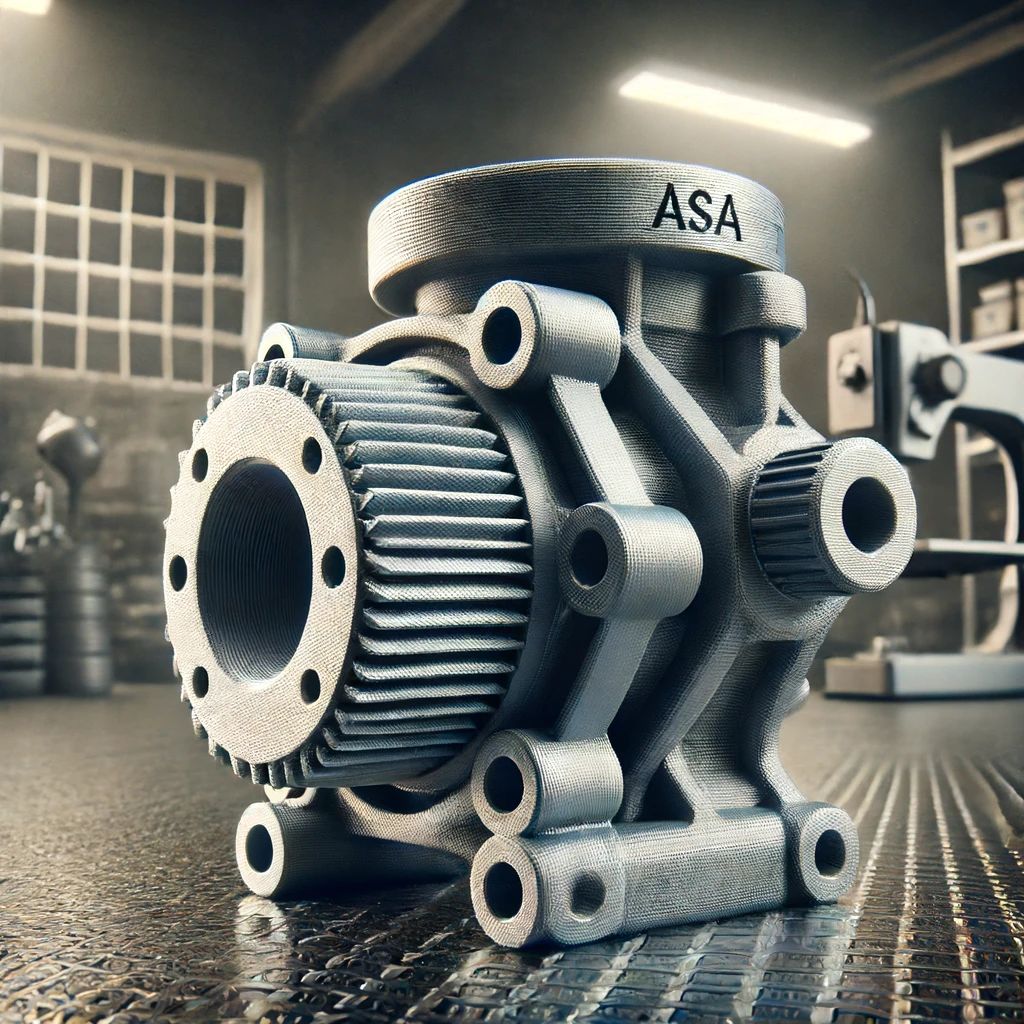

🌧️ ASA (Acrylonitrile Styrene Acrylate)

Think of ASA as a UV-resistant version of ABS. It looks and prints like ABS, but holds up better in sunlight. More expensive, though. I don’t always keep it in stock unless someone asks for it.

🔥 Polycarbonate (PC)

Super tough stuff. High heat resistance, great for industrial parts. Bit harder to print, needs high temps, and not always worth the hassle for simple outdoor jobs — but if you need strength and weather resistance, it’s worth a look.

💬 My Rule of Thumb

When a customer asks, I always say:

“If it’s going outside — garden furniture, greenhouse bits, external fittings — PETG is your friend. If it’s staying indoors, ABS is fine.”

And of course, it depends what it’s being used for. If it's just decorative? You’ve got more flexibility. If it’s structural or under load? Then we talk about infill, wall count, and post-processing too.

🧰 Want Me to Make Something That’ll Last?

That’s what I do here. Whether it’s one part or a full batch, I’ll help you pick the right material, design it properly, and get it made to last — especially if it’s going outside where the weather can do a number on it.

Send me a message, tell me what you’re working on, and I’ll point you in the right direction.