3D Printing: Innovations, Challenges, and Applications

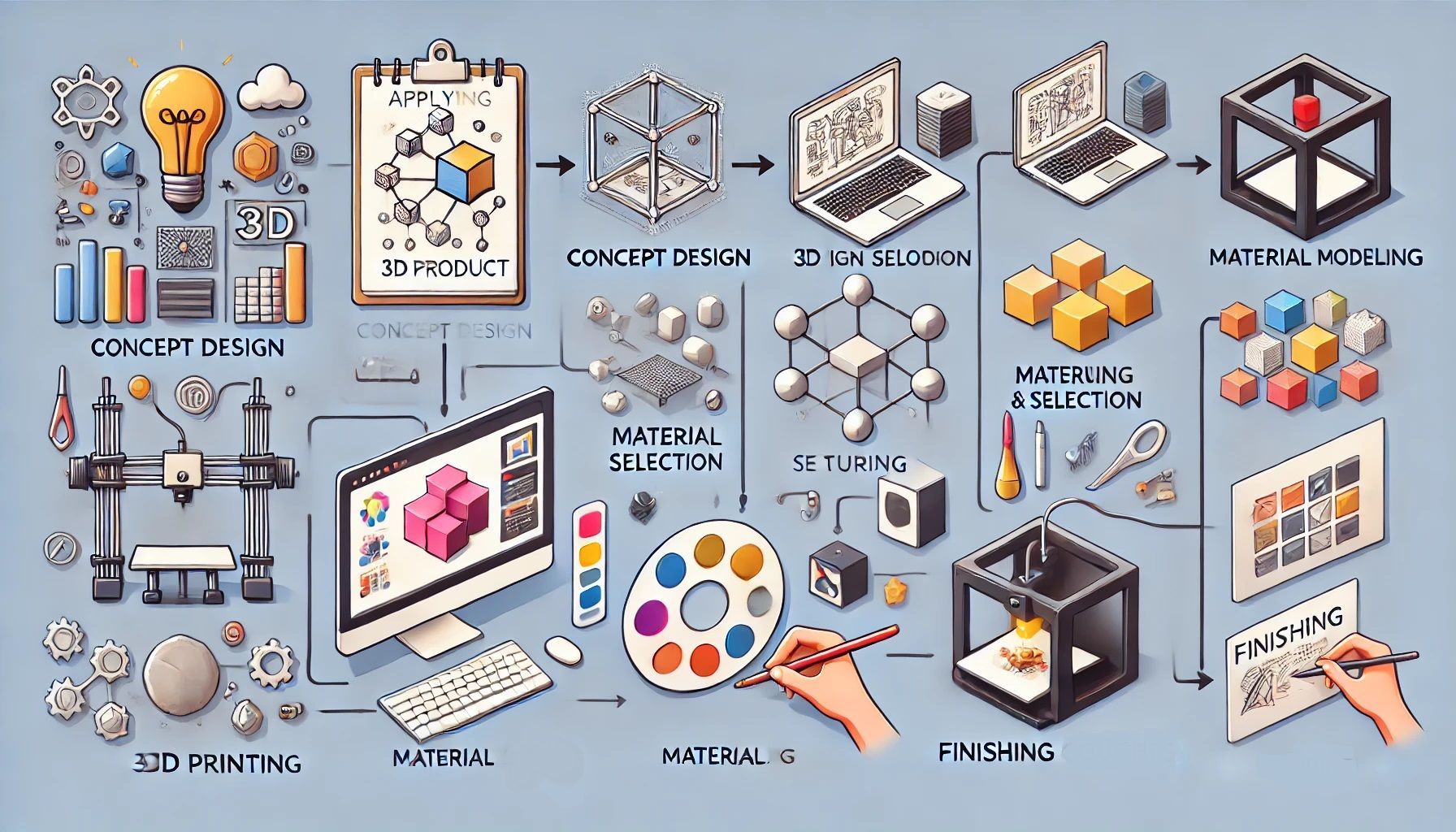

Applying Design Elements to 3D Printing

The world of 3D printing or Additive manufacturing is changing at a neck-breaking speed with new technology and new materials entering the market frequently.

What this means is that gone are the days of using 3D Printing to test a prototype of your product or just using 3D Printing to create gimmicky items, kids' toys, and tabletop game pieces.

We are moving into an era where 3D Printing is becoming the go-to tool for small batch production and to replicate a one-off functional part, with new types of Filament entering the market every month. Some of these composite materials have very high tensile strengths and will perform better if not equal to some of the metal parts ..

In this article, I would like just to touch on a few aspects of the 3D Printing Market that will change the way we use these types of services in the future.

Current Developments in 3D Printing

Revolutionizing Manufacturing Processes

The current landscape of 3D printing is characterized by significant breakthroughs that are revolutionizing manufacturing processes.

These developments are not just incremental improvements but game-changing innovations that redefine what's possible in additive manufacturing.

We know that companies like Bambulab and others already have the option to print multi-materials making a full-color 3D print possible.

At the end of July 2024, Creality will also be launching their K2 Plus which will allow the user to print with 4 - 16 different colors in a single print.

- Hyper 3D Printing: Hyper 3D printing is pushing the boundaries of speed and precision, making it possible to produce complex parts faster and with greater accuracy than ever before. This technology leverages advanced algorithms and cutting-edge materials to deliver superior performance.

- Sustainable Materials: There is a growing emphasis on sustainability in 3D printing, with new materials being developed that are both eco-friendly and high-performing. Biodegradable polymers and recycled materials are becoming more prevalent, aligning with the global push towards greener manufacturing practices.

- Enhanced Software Integration:

The integration of AI and machine learning into 3D printing software is another exciting development. These technologies optimize printing parameters in real-time, reducing errors and improving efficiency.

Challenges in Applying Design Elements to 3D Products

Despite the impressive advancements, several challenges remain in applying design elements to 3D products. Understanding and addressing these challenges is essential for achieving the best results.

When creating a 3D Model for a CNC machine there are many parameters that you must consider when designing and the same goes for creating a design for 3D Printing, even though the designs can be far more complex there are things that must be considered.

I have just highlighted a few of these below:

- Surface Finish and Detail: Achieving a high-quality surface finish can be challenging, particularly for intricate designs. Advanced post-processing techniques, such as polishing and coating, are often required to enhance the final product's aesthetics.

- Material Compatibility: Not all materials are suitable for every design. Designers must carefully consider material properties and compatibility to ensure structural integrity and functionality.

- Dimensional Accuracy: Maintaining dimensional accuracy throughout the printing process can be difficult, especially for large or complex parts. Continuous calibration and monitoring are necessary to mitigate this issue.

Specific Use Cases and Practical Insights

Print Speed for ASA

ASA (Acrylonitrile Styrene Acrylate) is a popular material in 3D printing due to its excellent weather resistance and mechanical properties. However, achieving optimal print speed without compromising quality requires careful consideration of several factors:

- Extrusion Temperature: ASA typically requires a higher extrusion temperature, around 240-260°C. Ensuring your printer can consistently maintain this temperature is crucial for achieving good print speed and quality.

- Layer Height: A smaller layer height can enhance surface finish but may reduce print speed. Finding a balance between layer height and speed is key to efficient printing with ASA.

- Cooling: Adequate cooling is essential to prevent warping and ensure layer adhesion. Using a part cooling fan can help maintain print quality at higher speeds.

Best 3D Printer for D&D Miniatures

For enthusiasts and hobbyists, choosing the best 3D printer for creating D&D miniatures involves considering factors such as detail resolution, material compatibility, and ease of use.

- High Resolution: Look for printers capable of printing at a high resolution, ideally 20-50 microns. This ensures that the fine details of the miniatures are accurately reproduced.

- Resin Printers: Resin 3D printers, like those using SLA (Stereolithography) or DLP (Digital Light Processing) technologies, are excellent choices for miniatures due to their superior detail and smooth finish.

- Software and Support: A user-friendly software interface and strong customer support can significantly enhance the printing experience. Brands like Anycubic and Elegoo are known for their robust support systems and high-quality printers.