3D Printing Resin

Resin – Sharp Detail, Smooth Finish, and Precision You Can Rely On

Overview

Standard SLA resin isn’t about brute strength — it’s about getting your part to look and feel like the finished product. It’s what we use when a customer says, “I need it to be clean, accurate, and ready to show.”

This is the material that sells your idea before it ever hits production. We use it for prototypes, presentation models, and anywhere you need detail, tight tolerances, and a part that just looks right.

You don’t use it to build brackets or mounts — you use it to get designs approved, to hold in your hand, and to move your project forward with confidence.

Key Technical Specifications (Typical Values)

• Tensile strength: 35–55 MPa

• Elongation at break: 4–10%

• Heat deflection temperature: ~50–60°C

• Shore hardness: 75–85D (depends on resin type)

• Surface finish: Very smooth – minimal layer lines

• Detail resolution: Down to 25 microns

• Impact resistance: Low to moderate

• Colour options: Greys, whites, blacks, clears, custom

Some resins are brittle, some are tough. We match the right resin to the job — visual, functional, or somewhere in between.

Why Engineers Use Resin

Resin is all about presentation and precision. Engineers and product teams use it when:

• They need a model to test fit and form

• Visual accuracy is more important than strength

• They’re designing small features, threads, or fine geometry

• They want to validate before committing to tooling

• They’re showing it to a board, a buyer, or a client

It’s what you use when the part has to look finished before it’s even real.

Where We Use Standard Resin

We’ve printed resin parts for:

• High-detail product mock-ups

• Medical and dental models

• Small, threaded prototypes

• Presentation parts for investor meetings

• Custom enclosures and casings for fit testing

• Engineering test parts before CNC or moulding

If it’s got tight tolerances, clean curves, or delicate features — resin is our tool of choice.

Printing Considerations

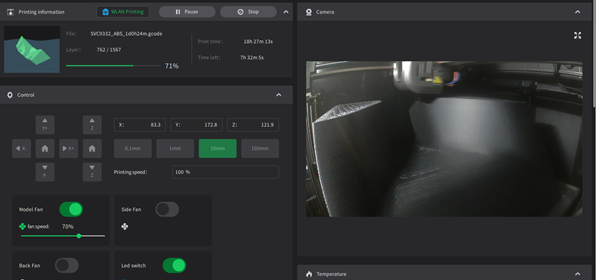

Now, SLA resin printing takes a different approach than FDM:

• It prints upside down in a vat of liquid resin — cured by UV light

• Supports are needed and must be removed carefully

• Post-processing includes cleaning and UV curing

• The part is solid — no infill patterns — so strength is consistent, but still brittle if over-stressed

We always ask: “Is this just to look at, or is it going to do some work?” Because that decides which resin we use — standard, tough, flexible, or heat-resistant.

Why Buyers Like Resin

For buyers, standard resin makes a lot of sense when:

• You need low-volume, high-detail parts quickly

• You're producing a client-facing model

• Tooling is still in discussion and you need approvals

• You want a model that looks like the final product — even if it isn’t

You’re not spending money to test production — you’re spending it to speed up decision-making. That’s where resin pays off.

Why We Use It at Mitchell & Son

One client needed a prototype of a handheld device to show investors — didn’t need to work, just needed to look the part. I said, “We’ll run it in grey resin, post-process it clean, and it’ll look like it’s come straight out of a mould.” He took it to the meeting and walked away with funding.

That’s what resin does — it helps ideas become real. Fast.

We don’t overcomplicate it. We just pick the right material for the job, and resin? That’s our go-to when first impressions count.

SOME INFOMATION ABOUT THE MATERIAL

Now, a lot of people have heard of 3D printing, but most think it’s just spools of plastic being melted through a nozzle. That’s one way of doing it, sure — but there’s another clever bit of tech called resin 3D printing. And let me tell you, it’s opened up a whole new level of accuracy and finish that the older filament printers can’t always match.

Here at Mitchellsson, this is exactly the sort of thing we help people with. Doesn’t matter if you’re running a factory that needs specialist parts or you’re just an everyday bloke with something broken at home — we can design it, print it, and save you a fortune compared to traditional manufacturing.

So, let’s break down resin printing in a way that makes sense.

🧴 What Is Resin 3D Printing?

Instead of feeding a plastic filament through a hot nozzle, resin printers use liquid resin stored in a container. That resin gets hardened, or “cured,” layer by layer until your part is finished. Simple as that. The big difference is in the how it’s cured, and that’s where the three main types of resin printing come in.

🔬 SLA – The Original Resin Printing Method

Stereolithography (SLA) has been around since the 1980s. It’s basically the granddad of resin printing.

How it works:

A laser beam shines onto the resin.

The light hits special chemicals called photoinitiators.

Those react instantly and solidify just the bit the laser touched.

Do that over and over, layer by layer, and before you know it, you’ve got a finished part.

SLA is brilliant for accuracy and surface finish. But it can be a bit slower compared to some of the newer methods.

🎥 DLP – Digital Light Processing

DLP works a lot like SLA, but instead of a single laser drawing each layer, it uses a projector. That means it flashes a whole layer at once, curing the entire cross-section in one go.

The result? It’s usually faster than SLA, especially for smaller or more detailed parts. It’s a great option when you need speed without sacrificing quality.

📱 LCD / MSLA – Resin Printing for Everyone

The newest kid on the block is LCD or MSLA (Masked Stereolithography). Instead of lasers or projectors, it uses an LCD screen. Think of it like a phone screen shining UV light through a mask, hardening the resin underneath.

The best part? LCD printers are cheaper to buy and run, but they can still hit really high accuracy. That’s why you’re seeing them everywhere now, from hobbyists’ garages to professional design studios.

🏭 Why Resin Printing Matters

So, what’s the point of all this? Well, resin 3D printing gives you:

High accuracy – sharper details than most filament printers

Smooth finishes – often straight off the printer

Versatility – used for prototypes, models, dental parts, engineering tools, and even end-use products

In other words, if you need a part that looks good and performs well, resin printing is worth considering.

👷 How We Help – Industry and the Man on the Street

This is where Mitchellsson comes in.

For industry: Maybe you’re running machines that need a small plastic component that no one makes anymore. Injection moulding would cost you thousands just for the tooling. With resin printing, we can design it in CAD, print it, and have it in your hands for a fraction of the price.

For everyday folks: Let’s say a plastic handle breaks on your lawnmower, or you’re restoring something vintage where the original part just doesn’t exist anymore. Bring it to us. We’ll measure it, redesign it, and print it stronger than before.

We’re not just here to make stuff look nice — we’re here to save people money, solve problems, and keep things working.

🧰 Our Process

Consultation – Tell us what you need, show us the broken bit, or give us an idea of what you want to make.

CAD Design – We design a 3D model. That’s vital because you can’t print off a flat sketch.

3D Printing – Using the right technology (filament or resin, depending on what’s best for the job).

Finishing – Sanding, priming, resin coating, or whatever extra strength or polish you want.

That’s it. Straightforward, no hidden nonsense.

💬 Final Word

Resin 3D printing might sound complicated when you first hear about lasers, projectors, and LCD curing, but at the end of the day, it’s just another way to get the job done.

And that’s what we’re about here — getting the job done properly, saving you money, and giving you a part that actually works.

So whether you’re a business needing prototypes or replacement parts, or you’re just someone trying to fix something at home, give us a shout.

We’ll walk you through the options, pick the right material and method, and make sure you end up with something that lasts.