3D Printing Service for Flint

Rapid Prototyping and Custom 3D Printing Solutions

1. What are the key properties of ABS filament?

ABS (Acrylonitrile Butadiene Styrene) is renowned for its strength and durability. It melts at approximately 220–250°C and requires a print bed temperature of 80–110°C to ensure proper adhesion. With a tensile strength of around 40–50 MPa, ABS is ideal for parts subjected to mechanical stress.

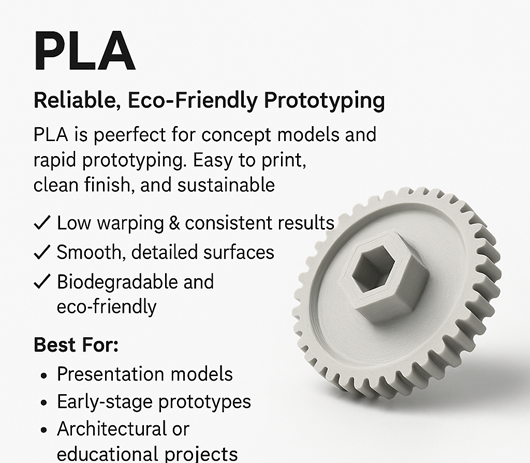

2. How does PLA filament perform in 3D printing?

PLA (Polylactic Acid) is favored for its ease of use and biodegradability. It has a melting temperature between 180–220°C and a recommended bed temperature of 50–60°C.

PLA offers a tensile strength of 50–60 MPa, making it suitable for prototypes and decorative items

3. What distinguishes PETG from other filaments?

PETG (Polyethylene Terephthalate Glycol) combines the ease of PLA with the strength of ABS. It melts at 220–250°C and adheres well to beds heated to 70–90°C.

PETG is known for its impact resistance and clarity, making it suitable for functional parts and containers.

5. What are the benefits of Nylon infused with Carbon Fiber?

Nylon + Carbon Fiber offers enhanced rigidity and strength. It melts at 240–260°C and benefits from a bed temperature of 60–80°C.

This composite boasts a tensile strength of 80–100 MPa and a flexural strength of 120–150 MPa, making it perfect for high-stress applications

6. How does TPU filament stand out?

TPU (Thermoplastic Polyurethane) is known for its flexibility and elasticity. It melts at 220–240°C and adheres well to beds heated to 50–60°C.

With a tensile strength of 20–25 MPa,

TPU is ideal for parts requiring flexibility, like gaskets and wearable items.

7. What are the characteristics of Polycarbonate filament?

Polycarbonate (PC) is prized for its strength and heat resistance. It melts at 250–300°C and requires a bed temperature of 80–110°C.

PC is suitable for high-impact applications and parts exposed to elevated temperatures

Testimonials

" Very helpful guys, patient too. Had a cool design to print a custom backplate for my Legion Go handheld device, and these guys stepped up and delivered!

Great communication and prompt delivery once the print was successful.

Of course the backplate fits perfectly, even clicks into place. Printed using PETG CF at a very competitive price.

I Highly recommend them! "

" I needed some very small plastic shelf support brackets, that were no longer provided by the manufacturer of my old SieMatic kitchen units.

Mitchell and Son Design were approached and produced a 3D model and then 3D printed the brackets very quickly, and to an excellent standard.

I highly recommend their service and expertise. "

" Posting on behalf of my father. He had four dust caps made for some Girling brake cylinders for a 1950s Riley 2.5ltr. They were perfect, spot on. Definitely recommended."

" A very nicely made part and these guys are easy to deal with, planning the next job right now."

Where to start and how?

Have you ever wondered how the magic of three-dimensional objects coming to life from mere digital files happens?

Welcome to the realm of 3D printing services, where dreams and designs converge to create tangible realities.

Across the UK, cutting-edge services offer "3D printing near me," harnessing Hyperspeed 3D Printing Technology to deliver faster, more efficient outputs. This isn't just about rapid prototyping anymore; it's about robust end-use manufacturing that meets the needs of diverse markets.

From automotive to fashion, the potential to tailor batch size production ensures price breaks and significant cost efficiency, making high-quality 3D printing accessible to everyone.

Dive deeper into the technical side, and you'll be fascinated by Fused Deposition Modeling (FDM). This popular method epitomizes the synergy of advanced materials with precision engineering, allowing for the creation of complex structures previously thought unachievable.

But it doesn’t stop there. The integration of automation and workflow optimization has revolutionized how projects are managed and executed, ensuring that every phase from design to production is streamlined for peak performance.

As a result, businesses can enjoy lower costs while pushing the boundaries of what 3D printing technology can achieve.

Meanwhile, the conversation about 3D printing is increasingly focusing on sustainability and circular manufacturing. The industry is moving towards materials that are not only advanced but also environmentally friendly, promoting a greener manufacturing cycle.

This shift is part of a broader trend of industry consolidation, where key players are coming together to standardize practices and drive innovations that uphold sustainability.

With such advancements, 3D printing is no longer just a tool for creation but a pivotal force in building a sustainable future, proving that the technology is not only about meeting today’s needs but also addressing tomorrow’s challenges.

Dwight Anton Mitchell

Sales and Operations Director

Dwight is our Sales and Operations Director, he brings a wealth of expertise to our team. With two decades of corporate sector experience in production support roles and a background as a trained motor mechanic, he has a proven track record of excellence. His career has included positions at renowned companies such as Eaton Aero Space, Wartsila, and Vertu.

Within our organization, Dwight has played a pivotal role in driving our most dynamic and impactful campaigns. His contributions have consistently led to revenue growth, acquisition of new clients, and the establishment of our clients as industry leaders.

Contact us any time

Contact Us

SIGN UP FOR OUR MONTHLY NEWS LETTER

3D Printing Service for Flint

Nestled along the estuary of the River Dee, Flint, UK, is rapidly carving a niche for itself in the revolutionary world of 3D printing.

Enthusiasts and professionals alike are finding a plethora of local services offering "3D printing near me," which leverage the cutting-edge Hyperspeed 3D Printing Technology.

This technology not only speeds up production times but also enhances the precision and versatility of manufactured items.

Flint's burgeoning sector is especially adept in Fused Deposition Modeling (FDM), a popular method that ensures robust and durable designs, making it perfect for both prototypes and functional parts.

The real game-changer for Flint's economy could be the focus on end-use manufacturing and batch size production.

With advancements in 3D printing, local businesses can now offer price breaks based on batch size, making it cost-effective for clients to order larger quantities.

This scalability is transforming industries from healthcare to automotive, where tailor-made parts and tools are being produced right at the threshold of demand.

The integration of advanced materials into the printing process further refines the output, offering unprecedented quality and functionality.

Behind the scenes, automation and workflow optimization are the unsung heroes in Flint's 3D printing saga.

These technologies not only streamline production processes but also significantly lower costs, making high-tech manufacturing accessible to startups and small businesses.

The result is a vibrant ecosystem where innovation thrives, and where the barrier to entry is lowered, inviting more players to the field.

This democratization of technology fosters a hotbed of creativity and cutting-edge development, reinforcing Flint's position on the tech map.

Sustainability and circular manufacturing also play pivotal roles in shaping the future of Flint's 3D printing landscape.

Local enterprises are increasingly adopting eco-friendly practices, aiming to reduce waste and reuse materials, aligning with global efforts to protect our environment.

This sustainable approach not only appeals to a growing eco-conscious consumer base but also sets a standard for industry consolidation, where efficiency and environmental responsibility go hand in hand. Flint, with its innovative spirit and commitment to sustainable practices, is setting a benchmark in the 3D printing industry, proving that small towns can indeed be at the forefront of big technological revolutions.