Choosing Suitable Materials for your project, is ASA or ABS or PC right for you?

MAKING THE RIGHT MATERIAL CHOICE

When having to decide on the type of materials to choose for your project, the choice can often be confusing as 3D Print Filament manufacturers and suppliers, often do not put all the required Mechanical data about the material onto the website.

Especially if you are buying through Amazon but also on their own websites. At times I have spent hours looking for the data sheets for a material because a customer will have specific requirements for the part that he wants to make.

I get bombarded with questions like, "What is the tensile strength of the material?", "Can the material you advised on withstand high temperatures?"

"Can this material withstand extended exposure to UV as it will be used in an external environment?"

Sometimes it is quite easy to get hold of this information depending on the type of material and the supplier, but for a large amount of time this info is very hard to find.

This is one of the reasons why I created a ChatGPT chat to help make finding this information easier and quicker than doing Google searches.

Click on this link if you want to or need to use the chat:

3D Print Mechanical Data ChatGPT

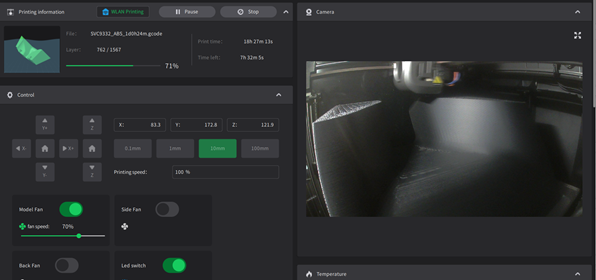

Below I have included a sample of the type of data that will be produced when you need to decide what type of material to use when 3D Printing a particular part.

With the above Data example, this part that a potential customer wants to make would need to be strong, UV resistant, and slightly flexible, our ChatGPT tool will allow you to find this information quickly and easily, displaying it in a comparison chart as above.

This will give you a better understanding of the material properties so that you can make an educated decision on which material to request from the selected 3D Printing Service supplier, taking the guesswork out of the process and potentially saving money as there would be less risk of printing a part in the wrong material and having to spend more on 2 or 3 prints before getting it right.

Material Suitability and Recommendations

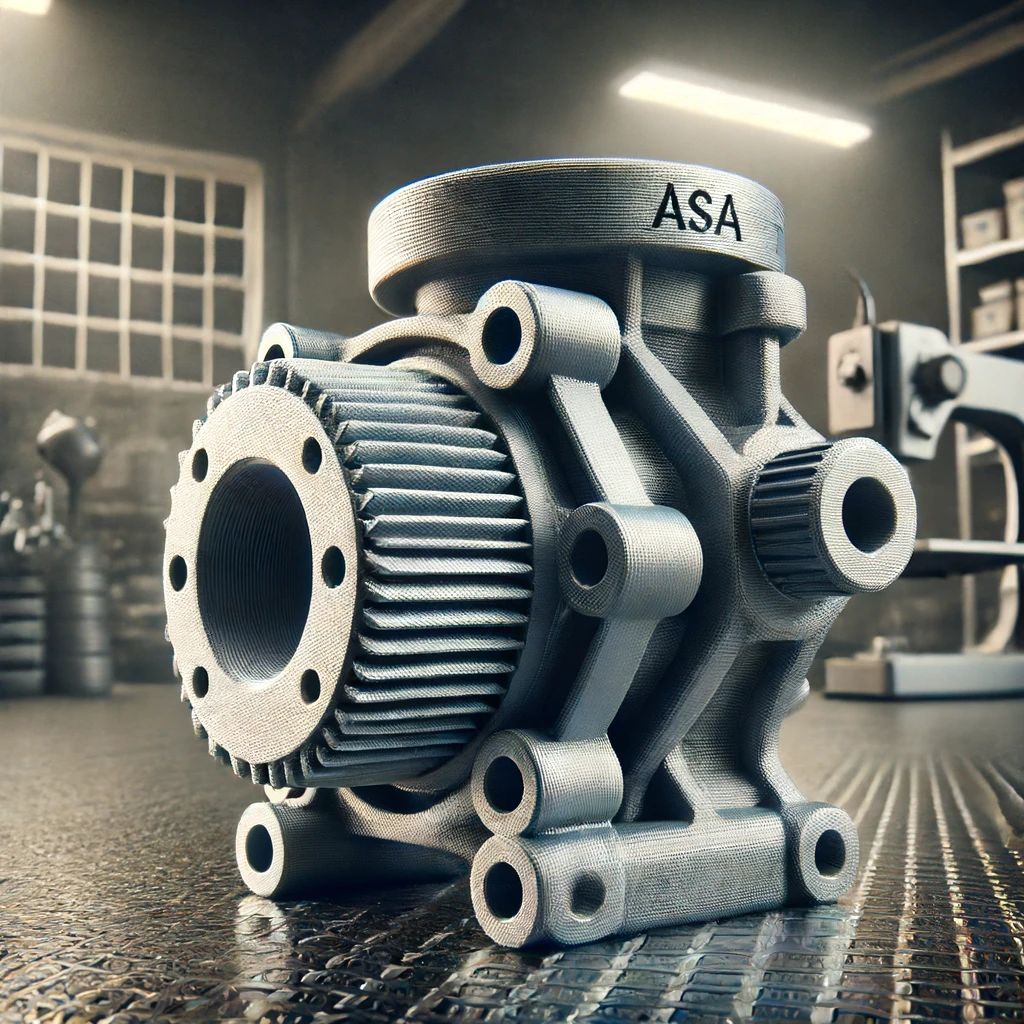

- ASA

- Strengths: Good UV resistance, suitable for outdoor applications. This material is industrial-grade and impact-resistant

- Weaknesses: Moderate chemical resistance and flexibility.

- Recommendation: Ideal for outdoor parts exposed to sunlight and moderate wear.

- These types of applications for would-be external automotive parts or sporting equipment and gear such a helmet

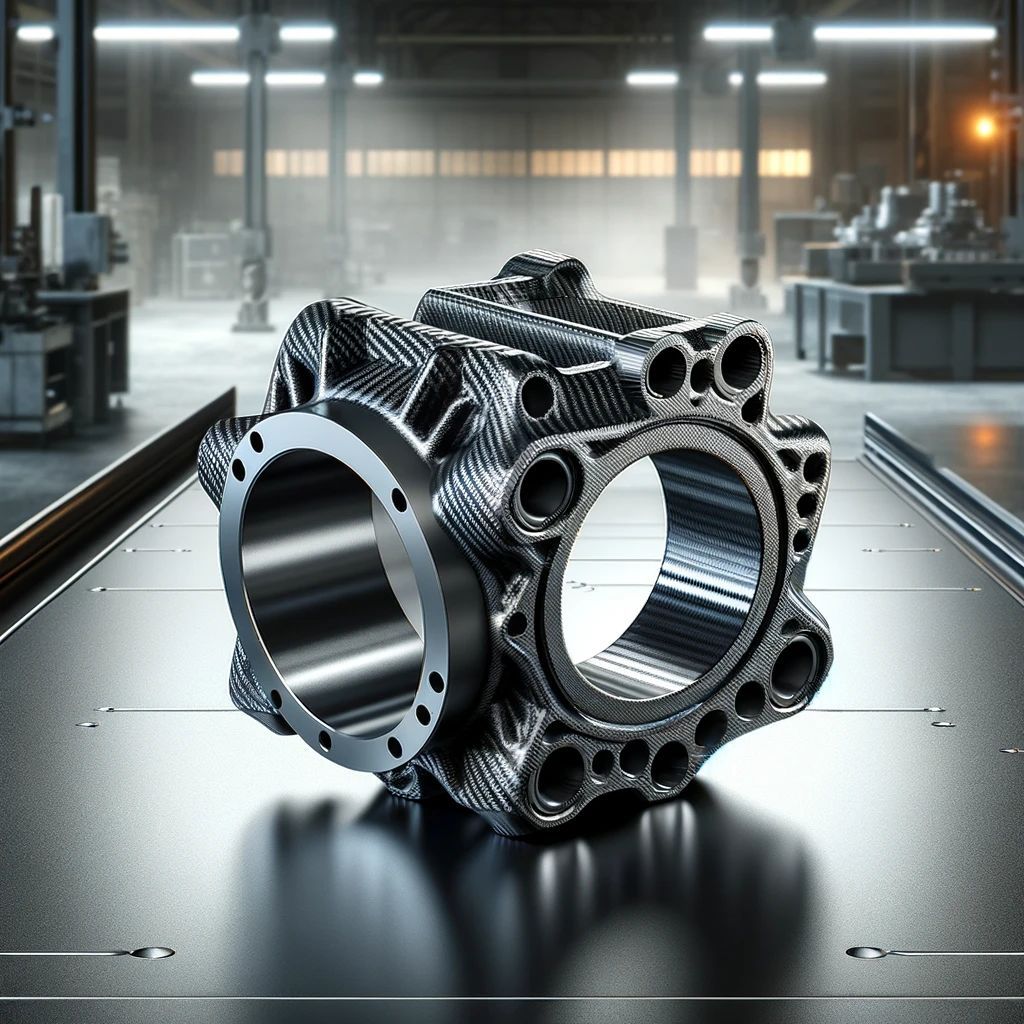

Nylon-CF (Carbon-Filled Nylon)

- Structural Components: Strong and rigid parts like brackets, frames, and supports.

- Automotive and Aerospace: High-strength, lightweight components for high-performance applications.

- Industrial Tools: Jigs, fixtures, and tooling requiring high strength and stiffness

PC (Polycarbonate)

- Protective Gear: Helmets, goggles, and other high-impact safety equipment.

- Automotive Components: Headlight lenses, instrument panels, and other high-strength parts.

- Electronic Enclosures: Durable and heat-resistant housings for electronic devices.