Nylon + Carbon Fibre

Nylon‑CF – Carbon Fibre Reinforced Nylon for High-Strength, Lightweight 3D Printing

Overview

Now, when strength really matters — when the part has to take a knock, hold a load, or just not fail under pressure — that’s when I turn to Carbon Fibre Reinforced Nylon, or Nylon-CF. It's everything you like about regular Nylon — toughness, flexibility, chemical resistance — but it’s reinforced with micro carbon fibres, so you get the strength of a structural material with the lightweight benefit of polymers.

I’ve used this material for clients where even the original injection moulded part kept failing. Instead of redesigning the whole system, we made the same part in Nylon-CF — problem solved. No tooling, no big bill, and it performed better than the factory version.

Key Technical Specifications (Typical Values)

• Tensile strength: 70–110 MPa

• Young’s modulus: ~6 GPa

• Heat deflection temperature: 110–180°C

• Elongation at break: 3–8%

• Density: ~1.2–1.4 g/cm³

• Excellent stiffness and dimensional stability

• Low thermal expansion (ideal for functional precision parts)

• Wear resistance: High (better than regular Nylon)

• UV resistance: Moderate

The carbon fibre gives the Nylon backbone — so you get high rigidity, less flex, and solid load-bearing capability.

Why Engineers Use Nylon-CF

Nylon-CF is a workhorse for structural prototypes and low-run production where metal strength isn’t necessary, but reliability is. It’s what you use when PLA’s too weak, ABS warps, and even standard Nylon isn’t stiff enough.

You’ll want to use Nylon-CF if:

• Your part sees real-world loads or impact

• You need consistent dimensional accuracy under stress

• You want something light but mechanically capable

• You’re bridging the gap between plastic and aluminium

This material isn’t just about looks — it’s about making parts that don’t just fit but hold, move, and last.

Common Applications

We’ve used Nylon-CF for:

• Load-bearing brackets

• End-of-arm robotic tooling

• Custom mechanical fixtures

• Replacement machine arms

• High-temp enclosures

• Automotive engine bay components

If it moves, flexes, or gets bolted onto something — Nylon-CF can probably handle it. We’ve done parts that take daily hammering, and they keep going.

Design & Printing Considerations

Here’s what we look at when printing Nylon-CF:

• It's abrasive – eats through brass nozzles, so we use hardened steel

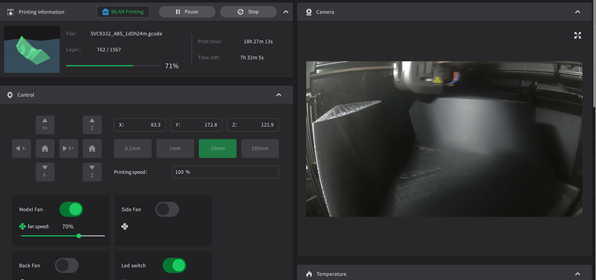

• It needs high heat – enclosed, high-temp printers only

• Print bed adhesion is crucial to avoid warping

• Part orientation makes a big difference on layer strength

If you're after full strength, we build with 100% infill and orient the layers to match the stress path — just like you'd align fibres in a composite. It’s not plug-and-play, but when done right, it’s solid.

Buyer Benefits

From a manufacturing or procurement perspective, Nylon-CF gives you:

• High performance without machining

• Zero tooling — perfect for low-volume or one-offs

• Fast turnaround (typically 2–4 days)

• Consistent quality over batches

• Real savings vs aluminium or CNC’d parts

It’s a proper industrial-grade material. No gimmicks. You get performance you can rely on and parts that can go straight into service.

Why We Use It at Mitchell & Son

Sometimes a customer brings in a broken metal bracket or a mount that just doesn’t last. Rather than go back to injection moulding or CNC, I’ll offer them this — Nylon-CF. We redesign it properly in CAD, add structural support where needed, and print it in this material. Saves them time, saves them money, and most importantly — the part holds up .

That’s the whole point of what we do — real-world solutions for real engineering problems.

SOME INFOMATION ABOUT THE MATERIAL

When it comes to printing with nylon, there are a couple of different types that you can choose from. Nylon filament infused with carbon fiber is by far the better option, as it is much easier to print with and doesn't have the same issues with shrinkage and deflection as regular nylon.

The carbon fiber in the nylon lowers the shrink rate significantly, and also stiffens it up so that it doesn't have the same degree of deflection as regular nylon. In our tests, it was over 100% stronger than PLA, and on average, 60% stronger than ABS.

If you are looking for a strong, durable, and easy-to-print material, then nylon filament infused with carbon fiber is the way to go.